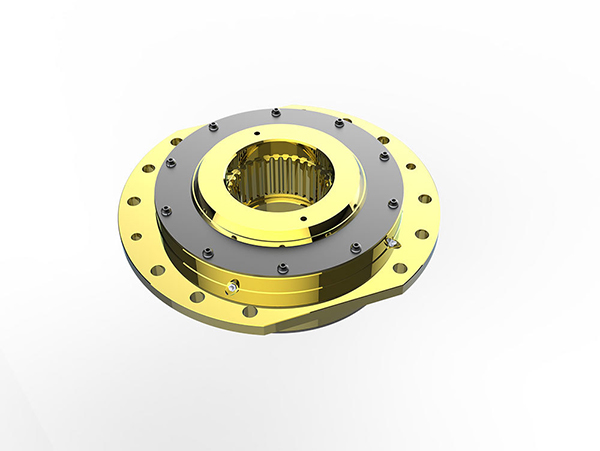

Sida qayb muhiim ah oo ka mid ah habka loo yaqaan 'STOREX', xaaladda shaqada ee a

giraangiraha transley theWaxay si toos ah u saameyneysaa amniga iyo waxtarka wax soo saarka. Isticmaalka dhabta ah, guuldaradii lugaynta ee caadiga ah ee Trolley giraangiraha ugu badan waxaa ka mid ah waxyaabaha soo socda:

I. Crance trolley giraan giraan dhasha iyo cillad

1. Xirashada UNILEATTAL: Tartanka rakibaadda ama isugeynta kulanka aan sax ahayn waxay horseedi kartaa xijaab xad dhaaf ah dhinac dhinac ah. Darajada balantterka ee qalad ah oo la soo saaray qalad heer-wado ah oo ka badan 3mm, taasoo dhalisay in billaha ah ee billaha ah 5mm, aad uga badan heerka amniga ee 0.5mm / bisha.

2. SPRENGING TREBING: Marka culeyska giraangiraha uu ka bato xadka daalka daalka (tusaale ahaan, giraangirta birta ee 55mn), tread-ka ayaa ku dhex dhacaya qaabka kalluunka. Giraanther crall grolley giraangiraha lagu sameeyay ee ku dhacaya waxay ku dhacdaa godad ilaa 8mm qoto dheer ka dib laba sano oo la isticmaalo.

3. Hoos-u-qaadid caag ah: Markaad ka shaqeyso bey'adda heerkulka-sare (> 150 ° C) ama culeys xad dhaaf ah, trailen giraangiraha ayaa burburin kara oo dilaali kara. Giraangiraha ku dhaca tolume trolley ee is-afgaradka aluminium ee elektrolytic ah ee ku shaqeeya heerkulka sare ee joogtada ah, taasoo keentay in ilko la dareemi karo oo lagu turunturoodo.

II. Qaadashada nidaamka fashilka

1. Qaadashada Qaadashada: Qaadashada saboolka ah waa sababta koowaad. Marka ku-meel-gaadhka ka-hortagga xakamaynta ay ka sarreyso 200 saacadood hawlgal, heerkulka qaadista ayaa si aad ah ugu kici kara ilaa 120 ° C. Khadka hufan ee xirxiran oo ku jira craseire ee loo yaqaan 'Craseis' ee saadka saadka ayaa sababay inuu dhaleeceeyaha dhaleeceeya inuu dhalaalo.

2. Xadhiga shaabadaynta: uumiga biyuhu wuxuu dardar geliyaa galka galka galka galka. Ka dib 18 bilood oo la adeegsanayo, Truleleyda Troleley ee Darajarka Darajada Dabayl Xeebta ee Xeebta Saadhaya Ku-meel-gaadhka u ah raashinka ku yaal raashinka raashinka awgeed iyo biyo-xireen.

3. Ciyaarta Axial Fashilkan ayaa sababay tallaabo 10mm ah oo ku taal wadajirka tareenka ee buundada buundada ee buundada.

III. Dillaac iyo jab

Crane Trollley giraangiraha1. Xadhiga dardaaranka: hoos yimaada xamuul, dildilaaca radial ayaa u nugul sameynta isgoyska giraangiraha giraangiraha. Tijaabada Ultrasonic ayaa shaaca ka qaaday in 15mm-qoto dheer-dillaac qarsoon oo ku jirta giraangiraha miraha macdanta ka dib markii uu socday 800,000 oo baaskiil wado.

2. Cilladaha tuurista: Ciladaha tuurista sida godadka ka hooseeya iyo pinholes waxay yareyn karaan xoogga giraangiraha. Guryaha cusub ee la beddelay ee lagu beddelay dhagaxa aasaasiga ah ayaa jabay ka dib seddex bilood oo la isticmaalo oo keliya. Faafinta ayaa shaaca ka qaaday daloolka 20mm oo ka jaban oo ku yaal bartamaha giraangiraha.

3. Dhiig balaaran: Jab jajaban ayaa dhacda marka culeyska saameynta uu ka bato xoogga maaddada taranka (e.g., σ 10 ≥ 1080 MPA 55mn bir ah). Shayga culus ayaa ku dhacay goob dhisme, taas oo keentay giraangiraha si dhaqso leh.

Iv. Raac Geynsiga iyo Raadinta

1. Skew Skew: Marka weecashada giraangiraha giraangiraha ay ka badan tahay 5mm, waxay sababi doontaa orodka abeeso. 32-ton ceyri ku jirta aqoon isweydaarsi ayaa la kulmay koror sadex laab ah oo ku jira xijaabka dhinaceeda oo ay ugu wacan tahay 8mm trolley Span farqi.

2. Skew trittw: Jiilaalka vertical-ka giraangiraha ka weyn 1 / 1000 wuxuu sababi karaa si lama filaan ah, raad-quseeya raad-qus ah. Cirkani wuxuu sababay in jaranjarada soo noqnoqda ee ku saabsan xaashida saxanka xargaha ee ku yaal dhalaalka daboolka. 3. U dhigma orodka oo liita Dareer 200-sano ah oo ku yaal geedka korantada wuxuu la kulmay 30% dhaqdhaqaaqa dhaqdhaqaaqa haatan jira sababta oo ah farqi 2mm kala duwanaansho 2mm ah oo lagu kariyo dhexroor.

V. Ciladaha la xiriira nidaamka korantada

1. Torque aan sinnayn Darajada dusha sare ee loo yaqaan 'Warehouse otomaatig' oo aan caadi ahayn oo lagu xiro oo lagu soo rogo marinka giraangiraha ee wadooyinka dartiis dartiis madynta tolque.

2. Faransiis Asynchrony: Farqi farqiga u dhexeeya tacabka> 0.5mm wuxuu sababi karaa warqadda curyaanka. Cirkani wuxuu sababay xoqitaanno xilli xilli ah oo ku yaal giraangiraha giraangiraha ee wadada tareenka dhulka hoostiisa ah.

3. Soocelinta Encoder: Jawaab celinta xawaaraha aan caadiga ahayn waxay sababi kartaa kala duwanaansho xawaare weyn. Darajada safka wax soo saarka gawaarida, biyuhu biyo ku leh waxay dhalisay 5% farqiga xawaaraha toosan ee ka dhexeeya labada jilibka.