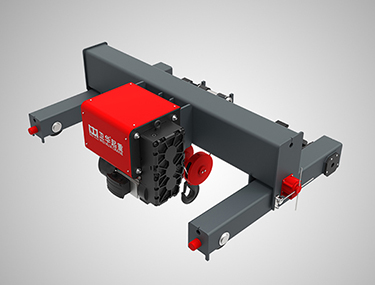

Njengengxenye ebalulekile yendlela yokusebenza ye-crane, isimo sokusebenza se

I-Crane Trolley WheelNgthelela ngqo ngokuphepha kwemishini yokuphepha nokukhiqiza. Ekusetshenzisweni kwangempela, ukwehluleka kwesondo le-trolley evamile ngokuyinhloko kufaka phakathi okulandelayo:

I. I-Crane Trolley Wheel Rim Gqoka futhi i-Deformation

1. Ugqoke u-Unilateral: Ithrekhi yokuphambuka kokuphambuka kokuphambuka noma ukuguqulwa kwesondo le-adcurate wheel kungaholela ekugqokeni ngokweqile ohlangothini olulodwa lwe-rim. I-tyry ganery crane yathola iphutha le-track level edlula i-3mm, okuholela ekugqokeni kwenyanga ngenyanga kwe-5mm, kudlula izinga lokuphepha le-0.5mm

inyanga.

2 Amasondo e-crane trolley wensimbi ahlanganisiwe athuthukiswe ama-proll dits afinyelela ku-8mm ekujuleni kwenhliziyo ngemuva kweminyaka emibili yokusebenzisa.

3. I-defformation yepulasitiki: lapho isebenza ezindaweni ezishisa kakhulu (> 150 ° C) noma ngaphansi komthwalo, i-Wheel Tread ingawa. Amasondo e-crane trolley ku-electrolytic aluminium workshop esebenza ngaphansi kwamazinga okushisa aphezulu aqhubekayo, okuholela ezinsukwini ezibonakalayo kanye nokuguquguquka kokunyathela.

II. Ukulwa Kwehluleka Uhlelo

1. Ukuthwala ukugcwala: ukuthambisa kabi kuyimbangela eyinhloko. Lapho isikhawu sokuvumelanisa sokuvuselela idlula amahora angama-200 okusebenza, izinga lokushisa elithwala lingavuka kakhulu ku-120 ° C. Umugqa wokugcotshwa okugcotshwe endaweni yokuhlanza esikhungweni se-Logistics wabangela ukuba umgcini we-earing ancibilike.

2. Ukwehluleka kwesivalo Ngemuva kwezinyanga eziyi-18 zokusebenzisa, ama-trolley bearings we-crane endaweni yemikhumbi yasogwini athuthukisa ukugqwala emjahweni ngenxa yokuguga nokungena kwamanzi.

I-3. I-Axial Play: Ama-Lockernuts akhululekile angadala ukufuduka okwedlulele kwe-axial (> 2mm), okuholele ekugqokeni kwesitimela. Lokhu kwehluleka kwabangela igxathu le-10mm ekuhlanganiseni kwesitimela se-crane yebhuloho lesiteshi samandla.

III. Ukuqhekeka nokuqhekeka kwe

Amasondo e-crane trolley1 Ukuhlolwa kwe-Ultrasonic kuveze ukuqhekeka okufihliwe okungu-15mm esondweni le-metallurgical crane ngemuva kokuthola imijikelezo yokulayisha engu-800,000.

2. Izinkinga Zokuphonsa: Ukuphonsa Iziphene ezinjenge-Shrinkage Cavities nama-Pinholes anganciphisa amandla wesondo. Isondo elisanda kufakwa esikhundleni se-foeldy crane liphuke ngemuva kwezinyanga ezintathu kuphela zokusebenzisa. Ukuhlukaniswa kwembulwa i-20mm shrinkage cavity esikhungweni samasondo.

3 Into esindayo yawela endaweni yokwakha, okwenza isondo liphumele ngokushesha.

IV. Landelela ukugoqa nokulandela umkhondo

1. I-Horizontal Skew: Lapho ukuphambuka kwe-diagonal yesondo kudlula i-5mm, kuzodala inyoka isebenze. I-crane engamathani angama-32 e-workshop enolwazi lokukhuphuka okungama-3

2 Leli phutha libangele ukuqhekeka okuvame ukugcwala ama-bolts e-track plate ku-terminal terminal crane. I-3. Ukuqhathaniswa kwethrekhi empofu I-crane engamathani angama-200 kwisitshalo samandla athola ukuguquguquka kwamanje kwama-motor angama-30% ngenxa yomehluko we-2mm kububanzi be-drive pulley.

V. Amaphutha ahlobene nogesi kagesi

1. I-Univether motor torque: Izilungiselelo ze-Inverter Parameter zingadala ukuhlukahluka kokuphuma kwe> 15% phakathi kwama-drive motor, ukugqokwa kwesondo okukhulayo. I-crane egumbini lokugcina impahla ezenzakalelayo athola ukugqokwa okungajwayelekile ku-wheel eqhutshwa yithonya ngenxa yokuntuleka kwesinxephezelo se-torque.

2. Brake Asynchrony: Umehluko we-Brake Cleance mehluko> 0.5mm angadala isiliphu sesondo. Leli phutha libangele ama-straks aqanjiwe esondweni elinyathela kwe-crane yethrekhi engaphansi komhlaba.

I-3. Ukuhluleka kwe-Encoder: Impendulo yejubane elingajwayelekile ingadala umehluko wesondo le-drive wheel. E-crane emugqeni wokukhiqiza wemoto, ukungena kwamanzi kwi-encoder kuholele ekutheni kube ngumehluko wejubane elingu-5% phakathi kwamaqhubu amabili okushayela.