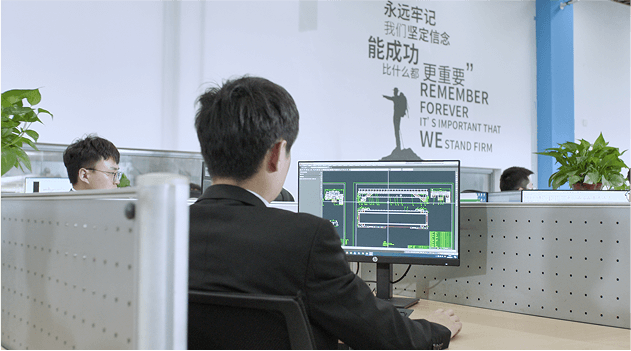

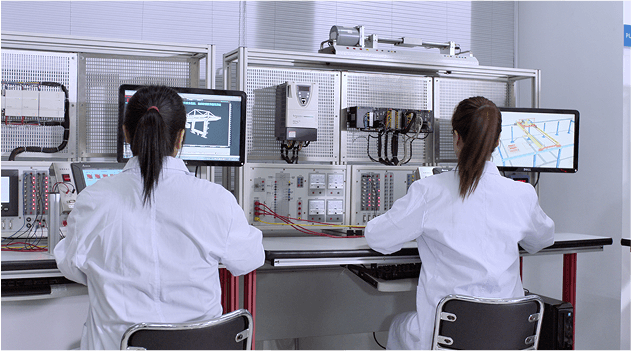

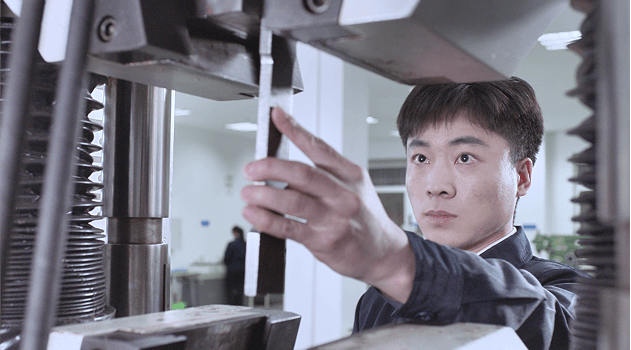

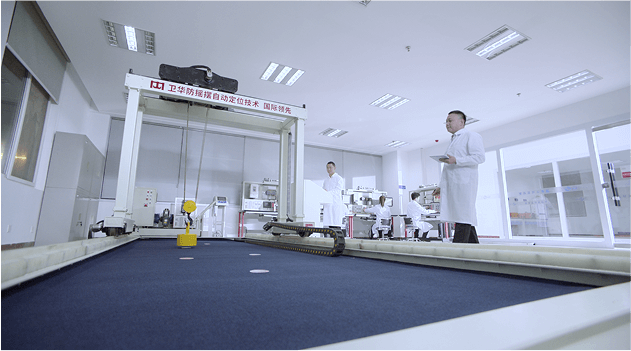

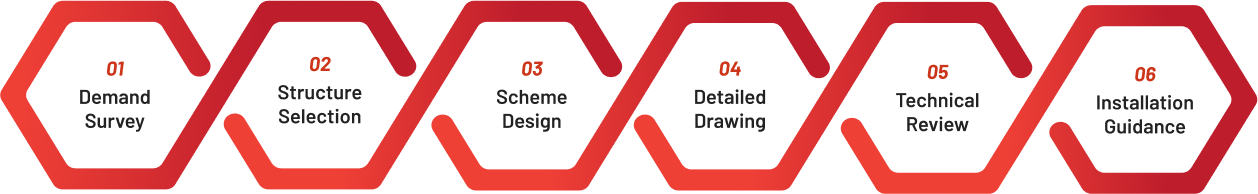

Weihua Crane is dedicated to providing customers with professional, efficient and safe crane project design services, covering the design and optimization of various types of bridge cranes, gantry cranes, tower cranes, jib cranes and customized lifting equipment. With rich industry experience and advanced technical means, we are committed to creating high-reliability and cost-effective lifting solutions for customers.