Overview of crane equipment in the metallurgical industry

As an important part of heavy industry, the metallurgical industry has huge material handling needs and special working conditions during its production process. Metallurgical cranes are special lifting equipment designed specifically for metallurgical production processes, with the characteristics of high working level, harsh environment, and frequent operation. Compared with ordinary cranes, metallurgical cranes have special requirements in structural design, material selection, safety devices, etc. to adapt to extreme working conditions such as high temperature, dust, and corrosive gases.

Main types of cranes in the metallurgical industry

1. Casting cranes

Casting cranes are the most representative lifting equipment in the metallurgical industry, mainly used for lifting and pouring molten steel in steelmaking workshops. Its main features include:

Ultra-high working level (usually up to A7 and A8)

Double trolley design, the main trolley is used for lifting steel barrels, and the auxiliary trolley is used for auxiliary operations

Special safety protection devices, such as double braking system, emergency power supply, etc.

High temperature resistant design, equipped with heat insulation board and other protective measures

2. Clamp crane

Specially used for handling hot-rolled steel plates in rolling workshops, the main features are:

Adopt hydraulic or mechanical clamp device

Rotating mechanism facilitates steel plate positioning

Heat-resistant insulated cables and electrical components

Precise positioning control system

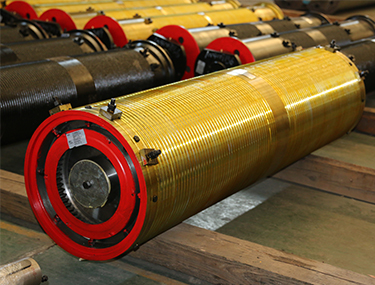

3. Electromagnetic crane

Mainly used for steel handling in cold rolling workshops and finished product warehouses:

Equipped with high-power electromagnetic suction cups

Automatic magnetic control system

Anti-sway design improves handling accuracy

Applicable to various forms such as steel plates and steel coils

4. Ingot stripping crane

Special crane used for ingot stripping operations:

Powerful lifting mechanism

Special clamp design

High-rigidity structure withstands impact loads

5. Forging crane

Heavy lifting equipment serving forging workshops:

Extremely high lifting capacity (up to hundreds of tons)

Precise speed regulation performance

Impact-resistant structural design

Key technical features of metallurgical cranes

High temperature resistant design: using thermal insulation protection, heat-resistant materials, thermal radiation shielding and other technologies

High reliability: redundant design, fault self-diagnosis system, multiple safety protections

Precise control: variable frequency speed regulation, anti-sway, automatic positioning and other advanced control technologies

Special structure: reinforced box beam, anti-deformation design, corrosion-resistant treatment

Intelligent monitoring: real-time monitoring of operating status, remote diagnosis, predictive maintenance

.jpg)