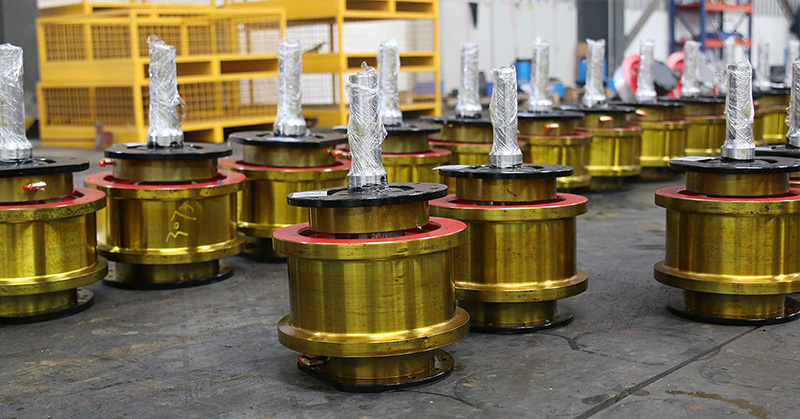

The wheel set is an important component of a bridge crane. The metal structure layout of the crane is closely related to the diameter and type of the wheel. The wheel set directly determines the overall structure and size of the crane.

Characteristics and methods of

crane wheel set selection and optimization

Reducing the wheel diameter has many benefits for the performance of the entire crane, mainly the following points.

(1) Reduce the height of the crane. The construction cost of a steel structure factory building is closely related to the height of the factory building. If the overall height of the crane can be reduced through the optimization design of the crane, it will undoubtedly be beneficial to saving the construction cost of the factory building. The wheel diameter directly limits the height of the crane end beam. If the wheel diameter can be reduced, the overall height of the crane can be reduced.

(2) Reduce wheel pressure and reduce factory building stress. At present, most hook-type bridge cranes in China with a lifting capacity of less than 50t use four wheel sets. For example, a crane with a lifting capacity of 50t and a span of 31.5m uses four wheels with a diameter of p800mm, and the maximum wheel pressure can reach 440kN. However, in foreign countries, cranes of this tonnage and span generally use eight small-diameter wheels. This disperses the pressure on the wheels, improving the stress conditions in the plant.

(3) Reducing the size of the drive unit. Reducing the wheel diameter reduces the driving torque, which can reduce the size of the reducer in the drive unit and save the cost of the drive unit.