Function and application of crane reducer

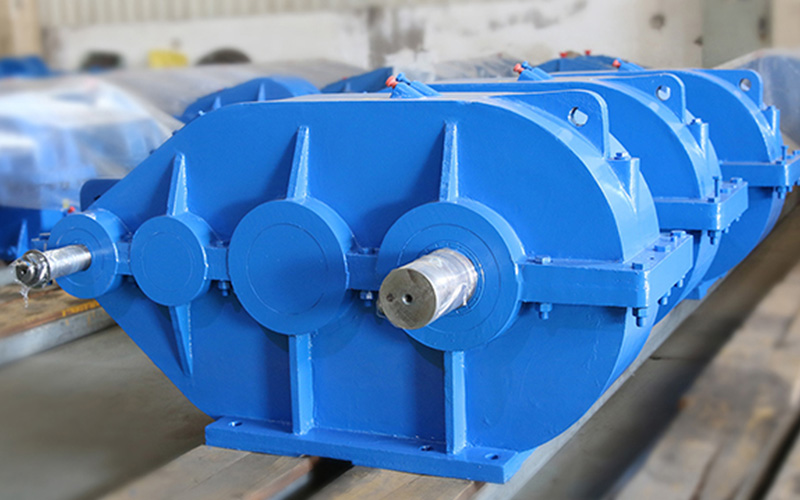

Crane reducer is the core transmission component of lifting machinery, responsible for converting the high-speed rotation of the motor into low-speed high-torque output, ensuring that the lifting equipment can smoothly and accurately complete lifting, luffing, rotation and walking. Its design must meet the requirements of long-term reliable operation under high load, frequent start and stop and harsh working conditions.

1. Main types

Lifting reducer: used for vertical lifting, with high torque and impact resistance

Running/traveling reducer: drives the crane trolley/cart to move, emphasizing smooth start and stop

Slewing reducer: controls the rotation of the boom, and needs to adapt to two-way alternating loads

Special reducer: such as explosion-proof type, metallurgical high-temperature type, marine corrosion-resistant type, etc.

2. Industry application

Engineering construction: tower crane, crawler crane lifting mechanism

Port logistics: shore crane, yard crane drive system

Metallurgical casting: continuous casting machine, ladle handling crane

Energy and power: wind power installation platform, nuclear power plant special crane

Special field: explosion-proof chemical crane, ship deck crane