The

crane hook group is the most common hook device in lifting machinery. The crane hook is suspended on the wire rope of the lifting mechanism with the help of pulleys and other components. The hook is the most widely used load handling device. It has the characteristics of simple production and strong practicality.

The hook group is the most common hook device in lifting machinery.

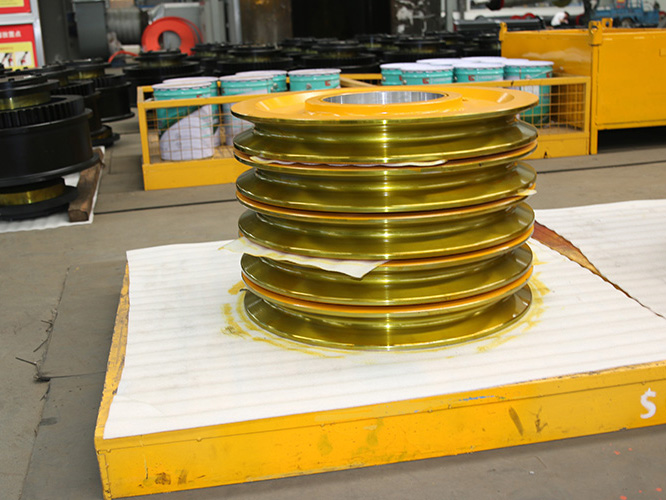

The hook is suspended on the wire rope of the lifting mechanism with the help of pulleys and other components.

The hook is the most widely used load handling device. It has the characteristics of simple production and strong practicality.

The crane hook is usually equipped with a safety latch to prevent the lifting wire rope sling, chain or rope connected to the load from detaching.

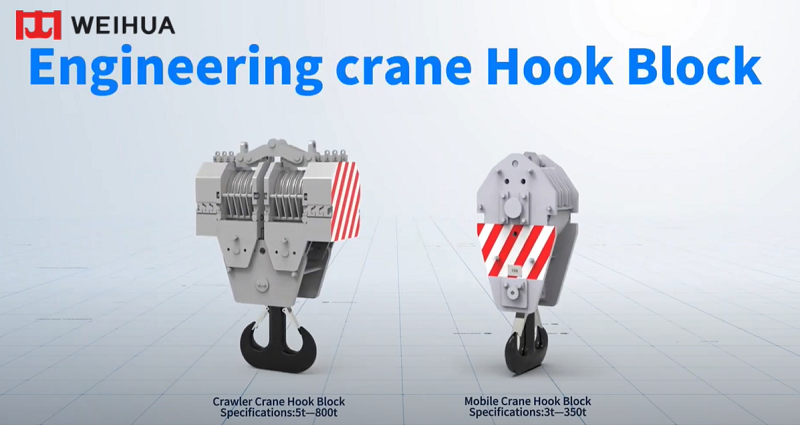

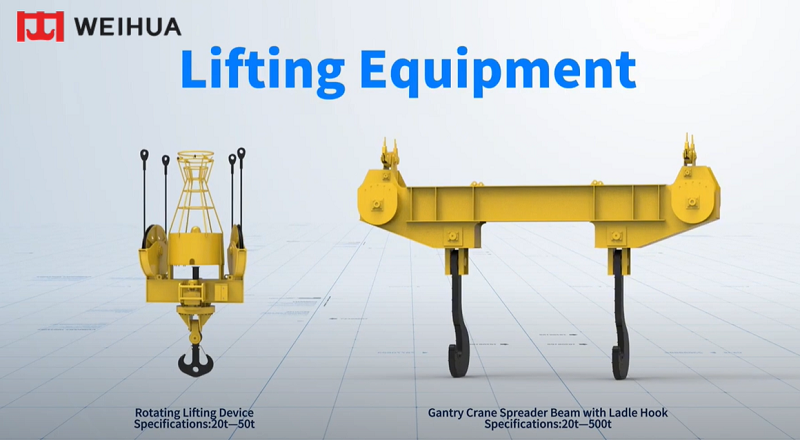

Different categories of crane hooks

Crane single hook: It is easy to produce and use, but its load-bearing capacity is poor, so it is mostly used only at low-capacity job sites (less than 80T).

Crane double hook: When the capacity is large, a symmetrically loaded double hook is used, which is divided into forging winch and tying winch according to the production method.

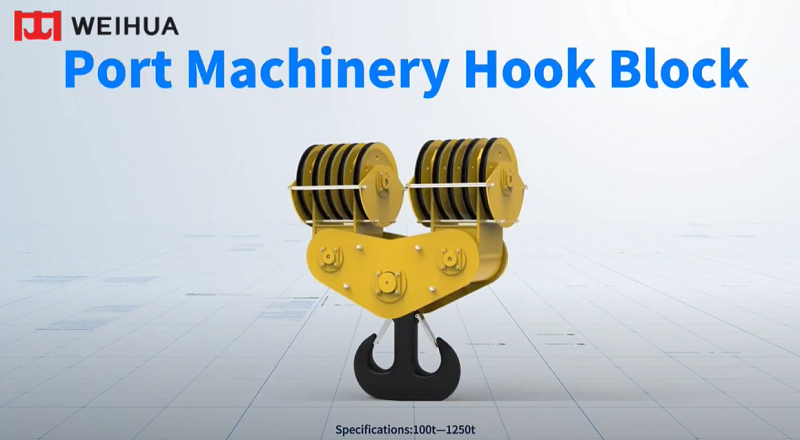

Forged winch hook: Made of multiple cut and formed steel plates riveted together, each steel plate has cracks, and the total hook will not break when used. It has good safety performance, but it has a large deadweight and is mostly used for cranes with large capacity or lifting molten steel.

Belt winch hook: Used for bridge, gantry cranes and various types of hoists.

Crane hooks should meet the manufacturer's recommendations and must not be overloaded. Problems will arise when using a crane hook that does not meet the manufacturer's recommended specifications. Specifically, this will increase the chance of equipment failure, resulting in personal injury and loss of production time. Crane hook failure can be caused by a variety of reasons, including overloading, mechanical damage to the hook, or accumulated fatigue. Our technicians' evaluation of the hook can help determine whether your hooks can meet your expected work requirements and whether they show any signs of potential failure.