Please first determine your three core requirements for the double-girder bridge crane: "span," "lifting height," and "working class." Provide detailed parameters to request a supplier to design a solution and provide a breakdown of quotes.

Factors affecting the price of a

10-ton double-girder electric hoist bridge crane (why there are large price differences):

Span of the double-girder electric hoist bridge crane: This is one of the most critical factors. The larger the span, the more material is used for the main beam, end beams, rails, and other structural components, resulting in a non-linear increase in technical requirements and costs.

For example, the price of a 10-ton double-girder hoist crane with a 10-meter span can differ by several times from that of one with a 30-meter span.

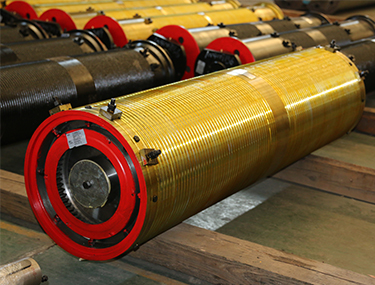

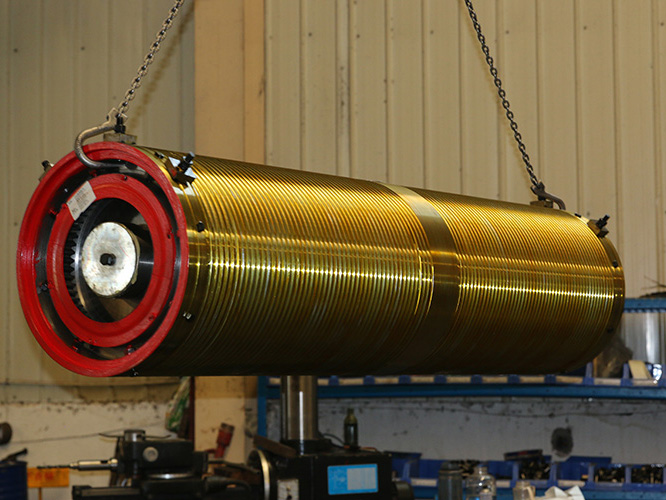

Lifting height: Standard lifting heights (e.g., 6-12 meters) and extra-high lifting heights (e.g., 18-30 meters) have different prices. The higher the height, the higher the requirements for the electric hoist's wire rope capacity and drum.

Working Level (Frequency of Use):

A3/A4 (Light to Medium): Suitable for general workshops and warehouses, intermittent use. Lower price.

A5/A6 (Heavy): Suitable for metallurgy, frequent loading and unloading, etc. Requires stronger structure, motor, and electrical components, significantly increasing price.

Main Component Brands and Configurations:

Electric Hoist: The core component. The price difference between mainstream domestic brands (Weihua) and imported/joint venture brands (such as Demag, Konecranes) is several times.

Electrical System: International brands such as Schneider Electric and Siemens PLCs, frequency converters, and contactors have significant cost differences compared to domestic brands.

The brand level of wire rope, motor, and reducer also affects the price.

Control Method:

Ground remote control (wireless/wired) is generally cheaper than cab control. However, advanced cabs (air conditioning, visual system) will increase costs.

Rail and Installation Requirements:

Prices usually do not include rail and installation fees! The procurement, laying, and commissioning of the rails (QU-type heavy rails), as well as the hoisting, installation, and inspection costs of the crane, constitute another significant expense, potentially accounting for 15%-30% or even more of the equipment cost.

Special Environments and Requirements:

Special environments such as explosion-proof, corrosion-resistant, high-temperature, and outdoor (with rain cover) require specific designs and materials, significantly increasing the price.

Is it necessary to specify special functions such as frequency conversion control (for soft start and precise positioning) or dual-speed lifting?