A large thermal power plant in Egypt is equipped with several heavy-duty bridge cranes (lifting capacity 50-200 tons) for equipment installation, coal-fired system maintenance and turbine unit overhaul. Due to high temperature, dusty environment and high-load operation, the cranes experienced track deviation, electrical system aging, brake failure and other problems, affecting the normal operation and maintenance of the power plant.

1.Comprehensive detection and diagnosis

- Laser calibration of track straightness (local deviation of 8mm/m was found, exceeding ISO standards)

- Infrared thermal imaging detection of hot spots in motor/cable joints (temperature exceeded 120℃ at 3 locations)

- Dynamic test of brakes (brake torque decreased by 30%)

2.Key maintenance items

- Replacement of German brand hydraulic brakes (with third-party certification)

- Upgrade of PLC control system, addition of overload protection module

- Ultrasonic flaw detection and local reinforcement of main beam welds

3.Customized maintenance plan

- Monthly cleaning of busbar carbon deposits (for coal-fired dust environment)

- Quarterly replacement of high-temperature gear oil (CLP 680 grade)

- Weekly lubrication of wire ropes (using graphite-based high-pressure grease)

Technical Challenges and Solutions

Modular Corrosion Protection

| Problem phenomenon |

root cause |

Solution |

| The vehicle is shaking when running |

Corrosion on track pads leads to loose bolts |

Epoxy grouting to reinforce foundation |

| Remote control signal interference |

Power plant electromagnetic field interference 2.4GHz frequency band |

Switch to the 868MHz frequency band with stronger anti-interference |

| Lifting mechanism hook |

Brake disc oil stain + spring fatigue |

Clean the disc surface + replace the disc spring (adjust the preload force to 110% of the design value) |

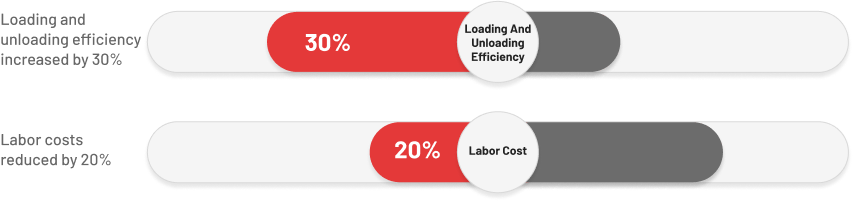

Service results

Safety improvement: Downtime rate decreased by 72% (compared with the data of 12 months before maintenance)

Cost optimization: Preventive maintenance extended the life of wire rope to 42 months (original average 28 months)

Compliance: Passed the annual inspection of special equipment by Egypt's NADCAP (National Aviation Defense Contractor Certification Program)

Highlights of localized services

- Equipped with Arabic technical documentation (compliant with Egyptian OSHA standards)

- Training power plant personnel on the use of vibration analyzers (on-site practical teaching)

- Local spare parts warehouse (common parts are stored in Cairo Industrial Zone

Didn't find your industry solution? Consult our technical experts immediately.

Experience summary:

This case shows that in harsh industrial environments, it is necessary to:

Shorten the maintenance cycle to 60% of the manufacturer's recommendation (e.g., gearbox oil change from 4,000 hours to 2,400 hours)

Use high-temperature resistant electrical components (e.g., use H-class insulation motors)

Dynamically adjust the maintenance plan (combined with the power plant overhaul cycle)

"The maintenance services provided by Weihua keep our cranes in excellent operating condition, ensuring continuous trouble-free operation during critical periods."

—— Amenhotep, Director of Engineering Department of Egypt Power Plant