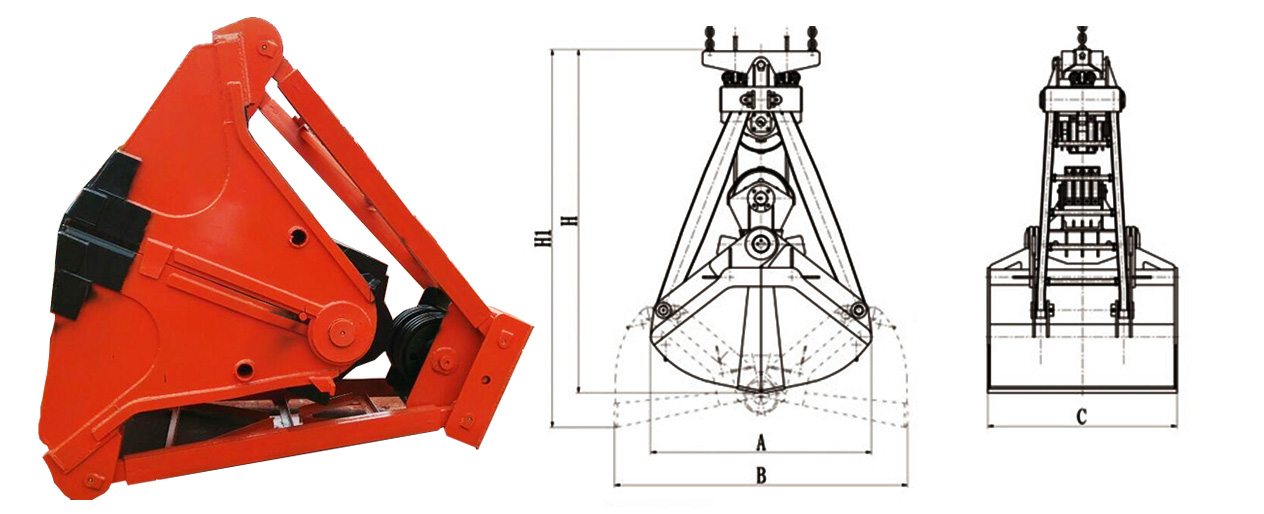

Double-flap Crane Grab Bucket is an ideal choice for handling medium and low density bulk materials with its sturdy and durable structure, efficient grabbing capacity and low maintenance cost. Its symmetrical double-flap design provides strong closing force and good sealing, which can quickly grab materials such as coal, sand, gravel, grain, etc., while reducing leakage and dust pollution. It has a simple structure and light weight, which reduces the crane load and saves energy consumption. It is especially suitable for small and medium-sized ports, construction sites and warehousing and logistics scenes with frequent operations.

Reliable sealing, environmentally friendly and economical

The gap is small after the double-flap is closed, which effectively reduces material leakage and dust flying, and meets environmental protection requirements; high-strength wear-resistant steel extends the service life, with lower long-term investment costs and outstanding cost performance.

Efficient grabbing and stable operation

The symmetrical double-flap structure with a strong closing system ensures fast and uniform grabbing action, which is particularly suitable for bulk materials such as coal, sand, gravel, and grain. It has a large single operation volume and a short cycle, which significantly improves loading and unloading efficiency.

Simple structure and convenient maintenance

Compared with multi-flap grabs, the double-flap design has fewer mechanical parts, a low failure rate, and easier daily maintenance. Key components (such as hinge shafts and hydraulic cylinders) adopt a modular design, which can be replaced quickly, greatly reducing downtime and maintenance costs.

Lightweight design and strong adaptability

It has light weight and balanced force, and has low requirements for crane load. It can be adapted to small and medium-sized gantry, bridge cranes and port equipment, saving energy and electricity, and is especially suitable for short-distance operations with frequent handling.