Magnetic lifting beam, also commonly known as a magnetic spreader beam or magnetic lifting girders, is a specialized lifting device that combines a lifting beam structure with electromagnetic chucks.

Simply put, it is not a single magnet, but a lifting device integrating multiple electromagnetic chucks, a balancing beam, and an electrical control system. Its main purpose is to safely and efficiently transport flat materials with magnetic properties, such as steel plates, billets, coils, and bundles of steel pipes.

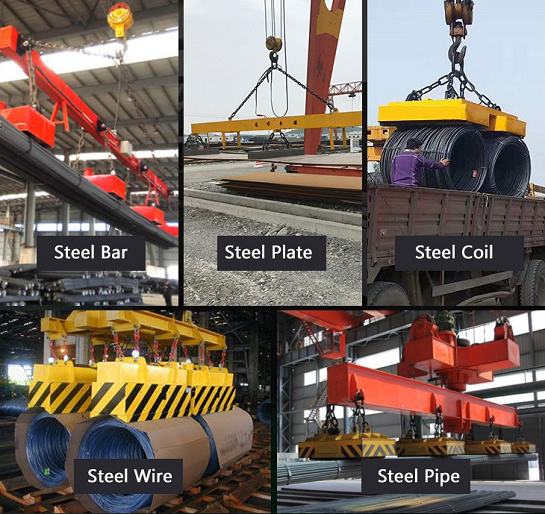

Lifting beams are used to lift large objects, such as steel plates, bundles of reinforcing bars, and pipes. Multiple magnets can be used simultaneously to move steel plates, pipes, and profiles of varying lengths.

A magnet spreader beam is a lifting spreader beam with electromagnetic lifters. It is a commonly seen lifting spreader in steel industry and manufacturing industry. This product is applied to lift and handle steel plates, sheets, billets, bars, coils, pipes, scraps, and other steel products. It usually works with overhead crane, gantry crane, or other hoists as a lifting device.

The electric permanent magnetic chuck does not need electric energy during the working process, and only relies on the permanent magnet suction to hold the workpiece, which avoids the danger of the electromagnetic system losing the magnetic force and the workpiece falling off due to sudden power failure and disconnection damage. Since the electro-permanent magnetic lifter only uses electric energy within 1-2 seconds of the magnetization and demagnetization process, it does not use any energy during work to generate safe, strong and efficient power, which is economical and environmentally friendly.

Magnetic lifting beam can be used with magnetic overhead crane or gantry crane to thick plates with thickness ≥5mm. Users can use multiple electro-permanent magnets for joint hoisting, with multi-stage magnetic adjustment function, and precise control of the magnetic penetration depth of the spreader, which can ensure that the next steel plate is completely non-sticky, which greatly improves the lifting efficiency of the steel plate. Different lifting tonnages Magnets can be grouped and controlled to adapt to steel plate spreaders of different lengths, which greatly improves the efficiency of steel plate lifting. The magnetic block can be round disc type, square type, rectangle type, etc.

When choosing a Magnetic Lifting Beam, you should pay attention to the following:

1. Characteristics of the Material Being Lifted:

Material: Must be a magnetically conductive material (e.g., ordinary steel, carbon steel). Non-magnetically conductive materials such as stainless steel (especially austenitic stainless steel), copper, and aluminum cannot be lifted using conventional electromagnets.

Shape and Size: Is it a steel plate, coil, billet, or profile? What are the length, width, and thickness/diameter of the material? This determines the beam structure and the layout of the suction cups.

Surface Condition: Is there rust, paint, or scale? These increase the air gap in the magnetic circuit, significantly weakening the adsorption force. Is the surface required to be free of scratches and indentations (e.g., mirror-finish stainless steel)? This will affect the material selection for the suction cup poles (e.g., adding a copper sheath or special coating).

Temperature: Is the material at room temperature or high temperature? Ordinary electromagnets are generally suitable for room temperature (-20℃ ~ +50℃). Lifting high-temperature steel (e.g., >100℃) requires a specially designed high-temperature magnetic lifting beam with special internal heat dissipation and insulation design.

2.Single Lifting Requirements:

Maximum Weight: The maximum weight of a single sheet/piece of material that can be lifted in a single operation.

Adsorption Method: Is it lifting a single sheet or extracting a single sheet from a stack of materials? Extracting a single sheet requires extremely high precision in magnetic field control and suction cup distribution.

Quantity Handled: Sometimes multiple items need to be lifted at once (e.g., a bundle of steel pipes, multiple steel plates). This requires calculating the total weight and adsorption stability.

3.Lifting Equipment Matching:

Crane Capacity: What is the rated lifting capacity of your crane? The weight of the magnetic lifting beam plus the weight of the material must not exceed this limit.

Lifting Height: Ensure the thickness of the lifting beam and the height of the lifting device are within the effective lifting space of the crane.

Hook Type: Must be correctly matched with the crane's hook.