In a German automobile welding workshop in Sao Paulo, Brazil, a 100-ton double-beam crane suddenly broke down:

Fault phenomenon : The main lifting mechanism slipped out of control and the trolley travel motor burned out

Impact : Production line shutdown, R$85,000 (about $160,000) per hour

Environmental challenges : workshop temperature 42°C + acidic welding gas corrosion

4-hour emergency response

The local service team arrives with FLIR thermal imaging cameras and vibration analyzers

Preliminary diagnosis: brake hydraulic valve stuck + motor insulation breakdown (caused by 90% humidity)

48-hour critical repair

| Faulty parts | Emergency measures | Long-term solution |

|---|---|---|

| Main lifting brake | Temporarily activate the spare friction plate | Replacement of IP65 protection grade wet brake |

| Travel motor | Calling for spare parts from Rio de Janeiro bonded warehouse | Upgraded F-class insulation winding |

| Control Cable | Bonding temporary shielding lines | Use acid-resistant CY type cable instead |

Corrosion protection

All bolts are replaced with A4-80 stainless steel

The junction box is filled with 3M Scotchcast moisture-proof gel

Heat dissipation modification

The motor is equipped with a German EBM axial flow fan (air volume increased by 40%)

Parallel backup circulation pump for reducer oil cooling system

Compliance and fast customs clearance

Priority customs clearance with Brazilian INMETRO certified spare parts

Maintenance personnel hold NR-12 Mechanical Safety Operation Certificate

Preventive advice

Weekly forced cooling system dust removal (for South American poplar season)

The brake hydraulic oil replacement cycle is shortened to 800 hours (50% of the original factory standard)

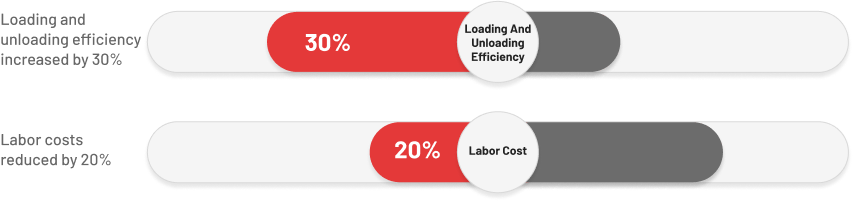

Downtime : Reduced from an estimated 72 hours to 51 hours

Cost control : Save 19% of tariffs through bonded warehouse spare parts

Subsequent improvement : Install Siemens S120 drive system fault pre-diagnosis module

Technical warning labels in Portuguese are mandatory

Priority is given to localized certified spare parts (such as wire ropes certified according to ABNT NBR 14753)

For rainy season humidity, polyether grease (compatible with mineral oil) is recommended.

— Budi Santoso, Head of Engineering, Port of Semarang