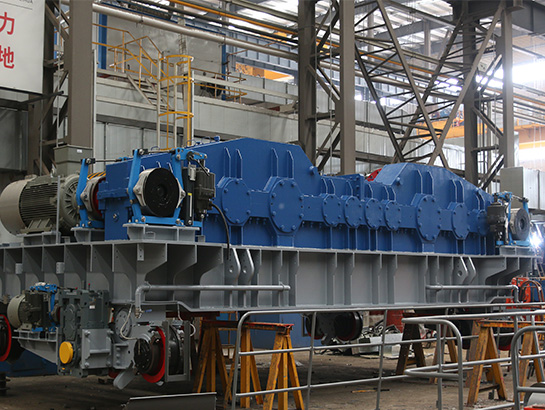

Line-Shaped Metallurgical Reducer is a heavy-duty industrial gearbox specifically engineered for the harsh operating conditions of the metallurgical industry, including steelmaking, continuous casting, and rolling mill applications. Characterized by its parallel shaft arrangement (linear "line-shaped" configuration), this reducer features robust construction with hardened gear teeth and high-strength alloy steel housings to withstand extreme loads, thermal stress, and frequent impact shocks. Its compact, modular design integrates advanced sealing systems and forced lubrication to ensure reliable operation.

The reducer adopts a modular design concept and can be flexibly configured according to the power requirements of different metallurgical equipment. The box structure has been optimized and has good heat dissipation performance and thermal deformation compensation capabilities, and can adapt to the high temperature environment generated by continuous casting, rolling and other processes. The gear transmission system has been precisely processed and dynamically balanced, and it runs smoothly and has low noise, which is particularly suitable for metallurgical machinery and equipment with strict transmission accuracy requirements. The product supports a variety of installation methods to meet the special requirements of different application scenarios such as metallurgical cranes, continuous casting straightening machines, and rolling mill transmissions.

Features a double-input and double-output structure with synchronous output, forced lubrication, balanced load, high load capacity, and strong impact resistance.