The wire rope drum is the core component of the hoisting mechanism, luffing mechanism or traction mechanism of the crane. It is used to wind, store and release the wire rope to achieve the lifting or horizontal movement of the load. Its design directly affects the life of the wire rope, the smoothness of operation and the safety of the whole machine.

1. Types of crane drums

(1) Classification by rope groove form

Smooth drum (no rope groove)

Suitable for multi-layer winding, but the wire rope is easy to be squeezed and worn, mostly used for auxiliary mechanisms or temporary equipment.

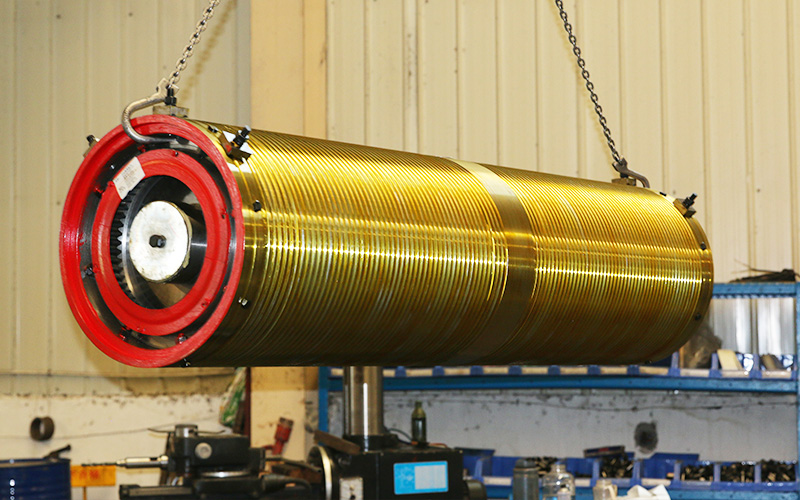

Spiral groove drum (single-layer winding)

The surface is processed with spiral rope grooves to guide the wire rope to arrange in an orderly manner, reduce friction and increase life (the most common type).

Standard groove: universal type, suitable for most cranes.

Deep groove: used for easy slot jumping or high vibration conditions (such as metallurgical cranes).

(2) Classification by structure

Single drum

Only one wire rope is wound, used for single-rope lifting or traction mechanism.

Double drum

Wire ropes are wound at both ends, used for double-rope synchronization system (such as balancing slings).