As a light and small lifting equipment,

electric hoists are widely used in many fields due to their compact structure, easy operation and strong load capacity. The following are its main application scenarios:

1. Industrial manufacturing field

Mechanical processing: used for loading and unloading machine tools and lifting parts on assembly lines.

Automobile manufacturing: handling large parts such as engines and car bodies, and coordinating the flow of production lines.

Metallurgical industry: electric hoists lifting steel ingots, molds or auxiliary equipment maintenance.

Chemical/energy: installing reactors, pipelines or maintaining heavy equipment (explosion-proof models are required).

2. Building and engineering construction

Site construction: electric hoists lifting building materials (such as steel bars, cement prefabricated parts), and assisting in the installation of steel structures.

Decoration and maintenance: electric hoists lifting curtain wall glass, air-conditioning units and other high-altitude working materials.

Bridges and tunnels: electric hoists used for equipment handling or construction assistance in narrow spaces.

3. Logistics and warehousing

Port terminals: loading and unloading small containers or bulk cargo (often used with gantry).

Warehouse management: stacking goods and handling pallets, especially suitable for high-rise shelf storage.

Freight station: loading and unloading goods on vehicles to improve efficiency.

4. Maintenance and installation

Equipment maintenance: hoisting motors, pump bodies and other mechanical parts for maintenance.

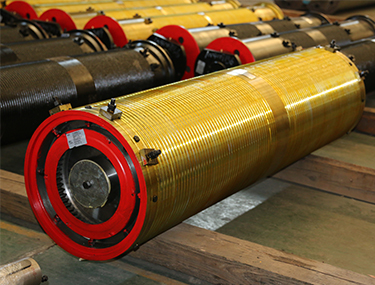

Power industry: installing transformers, cable drums, or building transmission towers.

Stage construction: lifting and lowering lighting and audio equipment (low-noise models are required).

5. Special scene applications

Clean workshop: using anti-static electric hoists in dust-free environments (such as electronics factories and pharmaceutical workshops).

Explosion-proof environment: using explosion-proof hoists in flammable and explosive places such as petroleum and chemical industries.

Shipbuilding: handling equipment or hull parts in narrow spaces in cabins.

6. Other fields

Agriculture: electric hoists lifting grain bags and feed in granaries.

Mining: handling small equipment underground (waterproof and dustproof design is required).

Emergency rescue: temporarily lifting obstacles or rescue equipment.

Selection points

Electric hoists different scenarios need to pay attention to:

Load requirements: ranging from 0.25 tons to 100 tons, 1-10 tons is common.

Power supply type: 220V/380V or battery drive (no power supply).

Environmental adaptation: high temperature, corrosion, explosion-proof and other special requirements.

Electric hoists installation method: fixed (I-beam track), running (with trolley movement) or hanging.

The flexibility and modular design of electric hoists make them an indispensable lifting tool in modern industry, especially in automated production lines, where they are often integrated with intelligent control systems to achieve precise lifting.