The deadweight of a 5-ton electric hoist varies depending on the model and configuration, but the typical range is between 500 kg and 700 kg.

Deadweight Comparison of Different 5-ton Electric Hoists

-

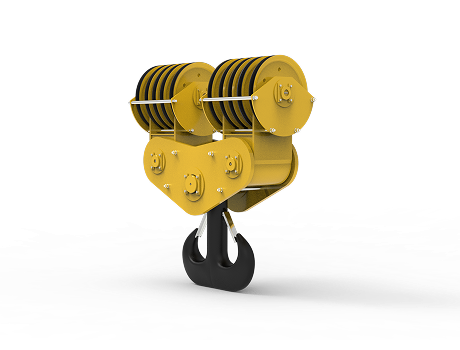

Wire Rope Electric Hoist: Deadweight approximately 550-700 kg

-

Chain Electric Hoist: Lighter deadweight, approximately 500-600 kg

Key Factors Affecting the Deadweight of an Electric Hoist

1. Structural Type:

- Wire rope hoists are generally heavier than chain hoists due to the complex structure of the drum and pulley assembly.

- Explosion-proof or high-temperature hoists may increase their deadweight by 10%-15% due to the thicker protective layer.

2. Material Selection:

Hoists made of high-strength alloy steel are approximately 20% lighter than those made of ordinary carbon steel, but they are more expensive.

3. Additional Features:

Features such as variable frequency control and dual-speed operation increase the weight of electrical components, potentially increasing the total weight.

III. Considerations When Choosing an Electric Hoist

- Scenario Compatibility: In factory environments with limited space or where frequent movement is required, it is recommended to choose a lightweight electric hoist (such as a chain hoist).

- Safety Verification: Ensure that the hoist's deadweight does not affect the load-bearing capacity of the supporting structure. For example, the I-beam track must match the total weight of the hoist (load + deadweight).