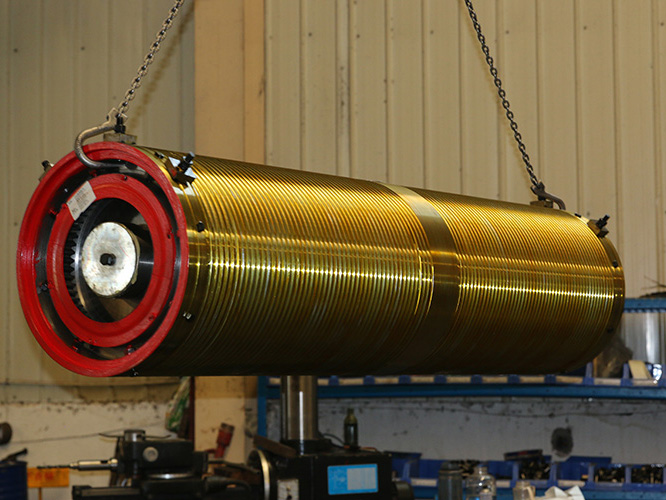

As a core component of a crane's traveling mechanism, the quality of the travel wheel assembly directly impacts the crane's service life and operating efficiency. The

wheel assembly, consisting of the wheel, axle, bearings, and bearing housing, primarily bears the crane's load and supports it, while also enabling the crane's travel and operation on the track.

Common Forms of Crane Wheel Damage:

Wear: The wheel surface gradually becomes thinner due to friction.

Crushing of the Hardened Layer: Excessive hardness of the wheel material causes crushing of the surface layer.

Pitting: Small pits appear on the wheel surface.

Crane Wheel Material Selection:

Wheels are typically made of ZG430-640 cast steel, with a heat-treated surface to enhance wear resistance and hardness. The tread hardness should reach HB330-380, with a hardened layer depth of at least 20mm to enhance the wheel's wear resistance and impact resistance.

The Importance of Crane Wheel Horizontal Deflection:

Wheel horizontal deflection is a key technical parameter for cranes. Excessive skew can cause rail gnawing, increased operating resistance, vibration and noise, and increased track and wheel wear, significantly shortening the crane's service life. Therefore, the manufacturing standards for various crane types specify the permissible range for horizontal wheel skew.

Inspecting the Crane Travel Wheel Assembly:

Inspecting the Wheel Wear: Observe the degree of wear on the wheel surface.

Inspecting the Wheel and Axle Fit: Ensure a tight fit between the wheel and axle.

Replacement Conditions: When the wheel wear reaches 15-20% of the original rim thickness or the flange wear exceeds 60% of the original thickness, consider replacing the wheel.

Quality Requirements for New Wheels: The wheel must be free of cracks, the rolling surface must be smooth and free of unevenness, and the axle-hole fit must meet design requirements. Wheel assembly quality requirements: The wheel and axle must fit securely, with a runout of no more than 0.10mm; the wheel's vertical tilt must be no more than 1mm; the bearing planes of the two bearing housings must be parallel to the wheel's width center plane, with an error of no more than 0.07mm; and the wheel must be positioned so that its width center plane aligns with the symmetry center of the two bearing housings.

The above inspection and maintenance steps can ensure the proper operation of the crane's traveling wheel assembly, extend the crane's service life, and improve operational efficiency.