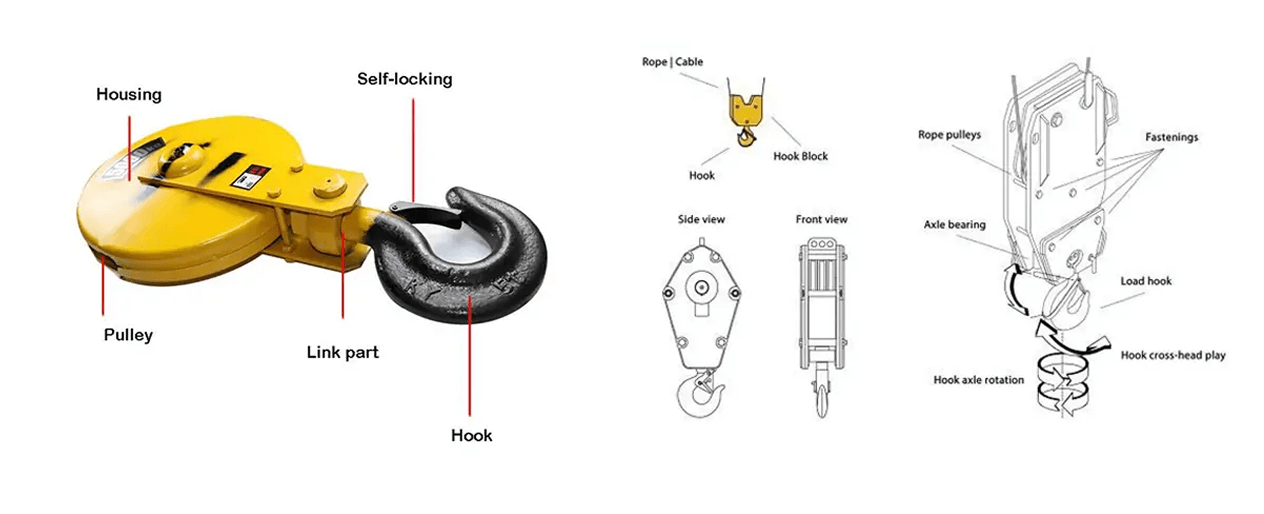

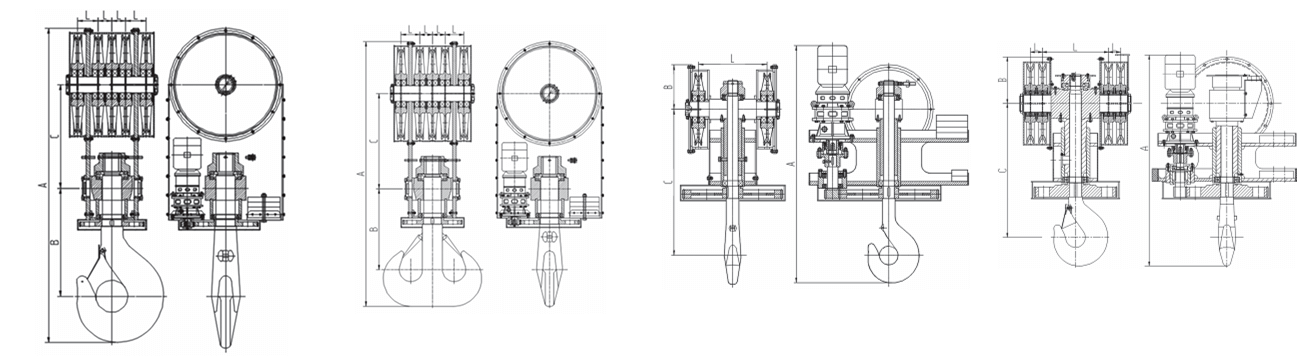

The hook of an electric hoist is the core load-bearing component of an electric hoist, and is mainly used for hanging, lifting and transporting goods. It is usually forged or rolled from high-strength alloy steel, and has excellent tensile strength and wear resistance. The hook structure includes a hook body, a hook neck, a bearing (or a thrust nut) and a locking device (such as an anti-unhooking safety tongue) to ensure that the heavy objects are stable and do not fall off during the lifting process. Depending on the lifting capacity, the hook can be divided into a single hook and a double hook, which are suitable for different tonnage operation requirements.

The hook of an electric hoist must comply with national or industry safety standards (such as GB/T 10051 "Lifting Hook"). Before use, check whether the hook has cracks, deformation, wear or rust, and perform regular flaw detection. Daily maintenance includes lubricating the hook neck bearing, checking whether the anti-unhooking device is effective, and avoiding overloading. If the hook opening is deformed by more than 10% of the original size or the torsional deformation exceeds 5%, it must be replaced immediately to ensure operational safety.

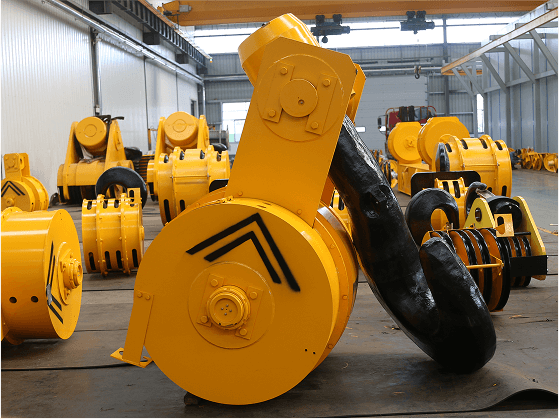

Electric hoist hooks are widely used for material lifting in factories, warehouses, construction sites and other occasions. When selecting the model, you need to consider the rated lifting capacity, working level (such as M3-M5) and use environment (such as corrosion resistance, explosion-proof requirements, etc.) of the electric hoist. For frequent operations or heavy load conditions, it is recommended to use double hooks or reinforced hooks with safety tongues to improve safety. In high temperature, low temperature or corrosive environments, special materials (such as stainless steel or galvanized) should be used to extend the service life.