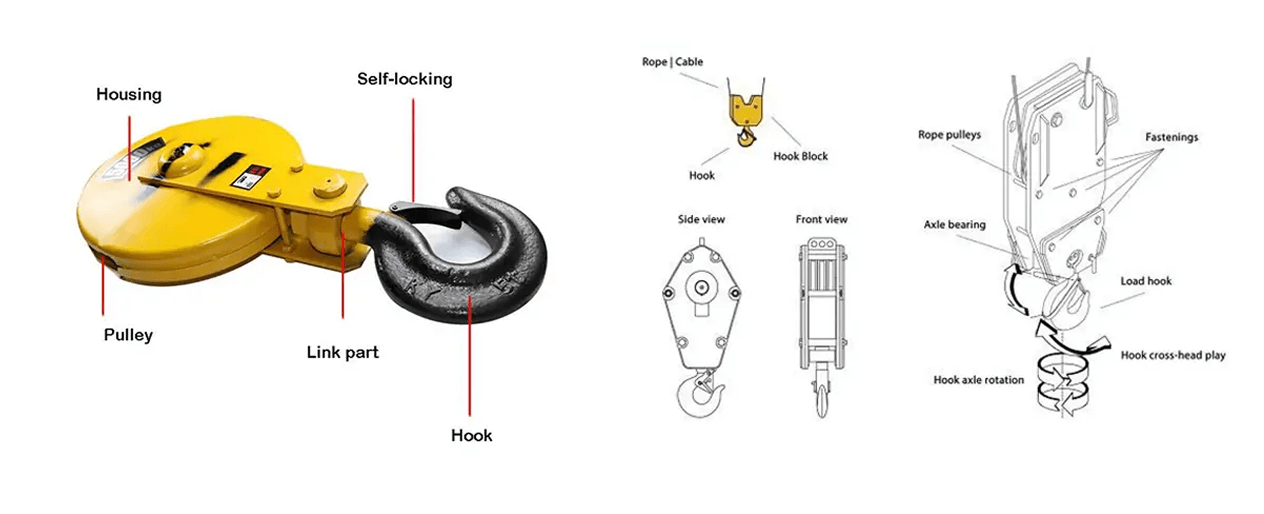

Crane hooks with safety locks are key equipment for ensuring the safety of lifting operations. Crane hook with safety latch can effectively lock the spreader when the equipment shakes, suddenly stops, or the load is unbalanced, preventing cargo from falling, equipment damage, and personal injury accidents caused by unhooking.

Intrinsic Safety, Preventing Accidental Disengagement

This is the core and fundamental advantage. The safety lock provides a physical barrier, eliminating the possibility of the sling slipping off the hook. Safety is ensured even in the following high-risk situations:

When the load swings or rotates: the hook sways due to inertia.

When the lifting mechanism suddenly starts or stops: the resulting shock and vibration.

When the operator is negligent: forgetting to check the hoisting status. The lock automatically closes under spring force, forming a reliable "safety gate" that minimizes the risk of disengagement.

Compliant with Regulations, Avoiding Legal and Compliance Risks

Safety regulations and industry standards in most countries and regions worldwide (such as China's GB/T, the US's OSHA/ASME, and the EU's EN) mandate the use of hooks with anti-disengagement devices in most lifting operations.

Legal Operation: Using hooks with locks is a prerequisite for legal and compliant lifting operations.

Avoiding Penalties: During safety inspections, using hooks without locks usually results in immediate work stoppage and rectification, and may face severe penalties.

Meeting Insurance Requirements: This is also a crucial prerequisite for purchasing engineering insurance and handling accident claims.

Boosting Operational Confidence and Efficiency

The psychological reassurance provided by safety devices directly translates into smoother operational processes.

Operators Feel More at Ease: Without the constant worry of the load falling during lifting, operators can focus more on precise positioning and coordination.

Commanders and Signalmen Feel More Reassured: The entire work team experiences increased safety.

Reducing Unnecessary Cautionary Stops: Less excessively slow operations due to fear of disengagement indirectly improve operational efficiency while prioritizing safety.

Protecting Assets and Reducing Overall Costs

While the initial purchase cost of a locking hook may be slightly higher, it significantly reduces overall costs over its entire lifecycle.

Preventing Damage from Falling Loads: Avoids major property damage such as the destruction or collision of heavy objects due to disengagement.

Preventing Secondary Damage to Equipment: Falling loads can damage equipment, structures, or other lifting devices below, causing cascading losses.

Reduce downtime losses due to accidents: Once a hook detachment accident occurs, the investigation, cleanup, and resumption of work will incur significant time and economic losses.

Extend crane hook life: The locking mechanism ensures the slings are always in the correct position within the hook cavity, reducing abnormal wear caused by friction and pressure on the hook tip.