| Type |

Load Capacity(T) |

Lifting Height(m) |

Lifting Speed (m/min) |

Traveling Speed |

Lifting Motor Power(kw) |

Rope Dia. (mm) |

Group(ISO) |

Rope Reeving |

| (m/min) |

| Single Girder |

3.2 |

6/9/12/15/18 m |

5/0.8 |

20/5 |

3.2/0.45 |

7 |

M5 |

4/1 |

| 5 |

6/9/12/15/18 m |

5/0.8 |

20/5 |

6.0/0.9 |

9 |

M5 |

4/1 |

| 6.3 |

6/9/12/15/18 m |

5/0.8 |

20/5 |

6.0/0.9 |

9 |

M5 |

4/1 |

| 8 |

6/9/12/15/18 m |

5/0.8 |

20/5 |

9.5/1.5 |

13 |

M6 |

4/1 |

| 10 |

6/9/12/15/18 m |

5/0.8 |

20/5 |

9.5/1.5 |

13 |

M5 |

4/1 |

| 12.5 |

6/9/12/15/18 m |

5/0.8 |

20/5 |

12.5/1.9 |

13 |

M5 |

4/1 |

| Double Girder |

5 |

6/9/12/15/18 m |

5/0.8 |

20/5 |

6.0/0.9 |

11 |

M5 |

4/1 |

| 10 |

6/9/12/15/18 m |

5/0.8 |

20/5 |

9.5/1.5 |

15 |

M5 |

4/1 |

| 12.5 |

6/9/12/15/18 m |

5/0.8 |

20/5 |

12.5/1.9 |

15 |

M5 |

4/1 |

| 16 |

6/9/12/15/18 m |

4/0.6 |

20/5 |

16/2.6 |

18 |

M5 |

4/1 |

| 20 |

6/9/12/15/18 m |

4/0.6 |

20/5 |

16/2.6 |

18 |

M5 |

4/1 |

| 20 |

6/9/12/15/18 m |

3.4/0.5 |

20/5 |

16/2.6 |

18 |

M5 |

4/1 |

| 25 |

6/9/12/15/18 m |

3.4/0.5 |

20/5 |

16/2.6 |

18 |

M5 |

4/1 |

| 40 |

6/9/12/15/18 m |

4.9/0.8 |

20/5 |

38 |

20 |

M5 |

4/1 |

| 63 |

6/9/12/15/18 m |

3.3/0.5 |

20/5 |

38 |

20 |

M5 |

4/1 |

Why Choose a European-Style Electric Hoist?

Why Choose a European-Style Electric Hoist?

The use of European-style electric hoists in industrial applications is indeed becoming increasingly common, primarily due to their advantages such as high efficiency, safety, space saving, and intelligent operation. Here are the core reasons for choosing a European-style electric hoist to help you better understand its value:

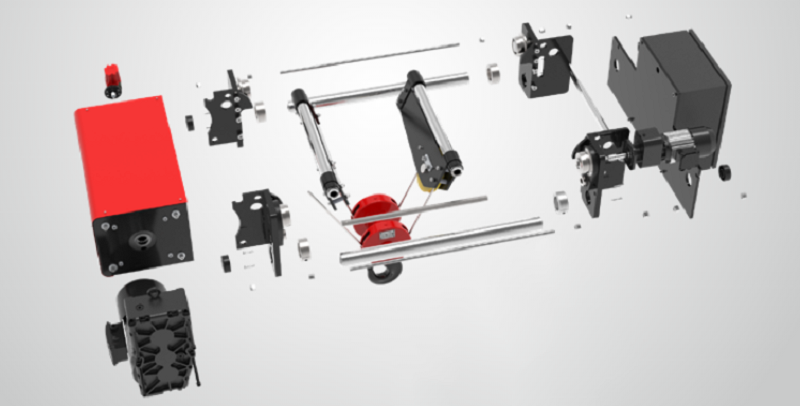

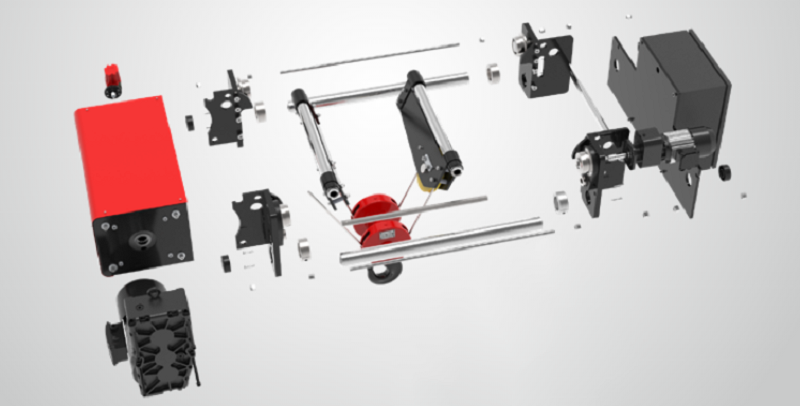

1. Compact Structure and High Space Utilization

Lightweight Design: Utilizing high-strength materials (such as high-quality alloy steel), the hoist reduces weight while maintaining strength, placing lower load requirements on the factory structure and tracks.

Optimized Size: Compared to traditional hoists, European-style hoists have a more compact design for components such as the drum and motor, reducing the overall size and making them particularly suitable for space-constrained workshops or high-rise lifting scenarios.

2. High Efficiency and Energy Saving

Advanced Motor Technology: Typically equipped with variable frequency motors or dual-speed/multi-speed motors, ensuring smooth start-up, precise speed adjustment, and reducing cargo swaying.

High Energy Efficiency: Some models employ energy feedback technology, consuming approximately 30% to 50% less electricity than traditional hoists, resulting in significant cost savings in the long run.

High Operating Level: Most models meet high operating levels (e.g., M4-M7) of FEM or ISO standards, suitable for frequent operation (e.g., hundreds of start-stop cycles per hour).

3. Safety and Reliability: Multiple safety protections: Standard features include overload protection, limit switches, emergency braking, and phase protection. Some models also feature intelligent monitoring systems (e.g., real-time monitoring of load and motor temperature).

Modular Design: Key components (e.g., motors, reducers, brakes) utilize a modular structure, facilitating maintenance and reducing failure rates.

High Protection Rating: Typically boasts IP55 or higher protection ratings, providing dust and water resistance, suitable for harsh environments such as humid and dusty conditions.

4. Intelligent and Automated Integration: Compatible with automation systems: Easily integrates with PLCs, remote control systems, or Internet of Things (IoT) systems, enabling unmanned operation, remote monitoring, and data analysis.

Precise Positioning: With a frequency converter, millimeter-level precision positioning can be achieved, meeting the needs of precision assembly and production line material handling.

5. Low Maintenance Costs

Long Lifespan Design: Gears utilize a carburizing and quenching process, extending the lifespan of the wire rope and reducing replacement frequency.

Convenient Maintenance: Modular components support quick disassembly; many models are equipped with diagnostic interfaces for early fault warnings, minimizing downtime.

6. Wide Range of Applications

Manufacturing: European-style electric hoists can be used in automotive assembly lines and machine shops.

Warehousing and Logistics: European-style wire rope hoists are used for stacking and loading/unloading.

New Energy Sector: Wind power equipment maintenance and photovoltaic panel installation.

Specialty Industries: European-style explosion-proof electric hoists can be used in explosion-proof environments (such as chemical plants and mines), high-temperature workshops, etc.