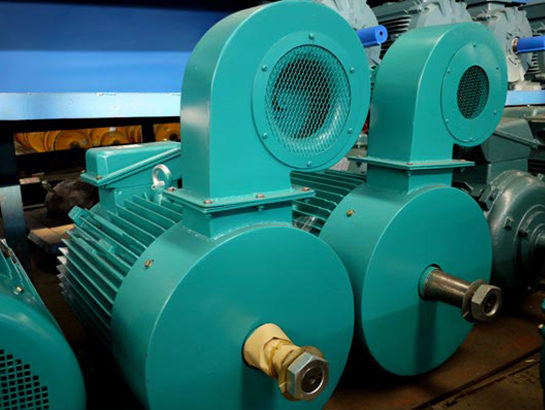

The crane motor is the core power component of the crane, providing efficient and reliable power output for the lifting, operation and slewing mechanism. The crane motor adopts a heavy-duty design with high starting torque and overload capacity to ensure stable operation under frequent start-stop and impact loads. The motor insulation level reaches F or H, with excellent temperature rise control, and effectively adapts to harsh environments such as high temperature and dust. Specially customized wound rotor motors or variable frequency motors can accurately match the differentiated needs of crane lifting and trolley/car operation.

The motor housing protection level reaches IP55/IP65, which is dustproof and waterproof. Some port models use anti-corrosion coating to resist salt spray erosion. The bearings use heavy-duty deep groove ball bearings or insulated bearings (anti-shaft current) to extend the maintenance cycle. Vibration, noise and durability tests are passed to ensure long life in high-frequency and high-load scenarios such as metallurgy, ports, and construction. In terms of maintenance convenience, a modular design is adopted, and the stator and rotor can be quickly disassembled and assembled, greatly reducing downtime.

Typical application scenarios: Bridge/gantry crane lifting mechanism, Tower crane slewing drive, Special explosion-proof motor for metallurgical casting, Port container crane travel system. WEIHUA provide different crane motors brands such as Jiamusi, Jiangxi Special Motors, Siemens, ABB, SEW, etc. We suggest the right brand motors and models according to the cranes you have.

.jpg)