As China's leading crane manufacturer, Weihua Group's bridge crane reducer is the core transmission component, which directly affects the operating efficiency, stability and life of the equipment. The following is a detailed technical analysis of Weihua bridge crane reducer/gearbox:

1. Common

crane reducer/gearbox types

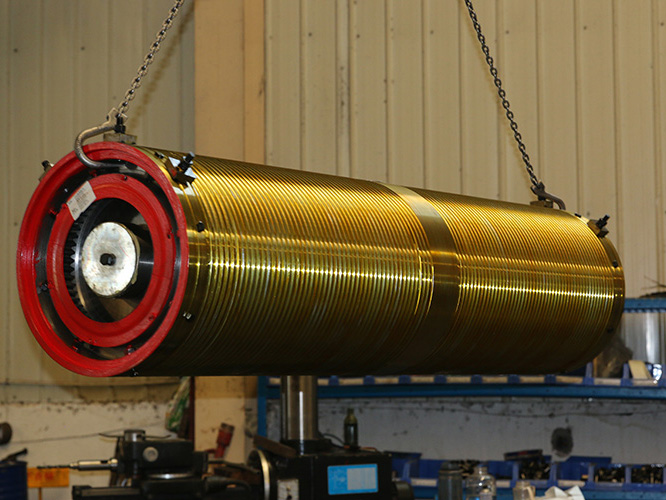

QJ series crane-specific reducer

Standard: in accordance with JB/T 8905 (equivalent to German FLENDER technology)

Features: three-stage helical gear transmission, hardened tooth surface (carburizing and quenching HRC58-62), high load capacity, suitable for lifting mechanism and trolley running mechanism.

Speed ratio range: 12.5~100 (common models such as QJRS, QJRD).

Three-in-one reducer motor

Integrated design: reducer + motor + brake integration, compact structure (such as SEW's K series, Weihua's self-made WH series).

Advantages: easy installation, suitable for trolley running mechanism or light crane.

2. Technical features of

Weihua crane reducer/gearbox

Material and process

The gear is made of 20CrMnTi alloy steel, and the grinding accuracy reaches ISO 6 after carburizing and quenching.

The housing is made of high-strength cast iron (HT250) or welded steel structure with good shock resistance.

Seal and lubrication

Double-lip skeleton oil seal + labyrinth seal, oil leakage prevention (IP65 protection level).

Forced lubrication (large reducer) or splash lubrication (small and medium-sized).

Adaptive design

The input shaft and the motor are directly connected through a coupling (plum blossom shape, gear type).

The output shaft can be selected as a solid shaft or a hollow shaft (with a locking disc), which is suitable for Weihua standard wheel set.