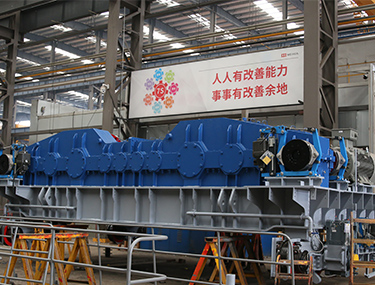

Stepping into Weihua Group's massive structural workshop, sparks fly and heat billows as the structural components of a giant port crane are being welded in sections. This is Weihua Group's new product, a 3,000-ton gantry crane, and the first of its kind manufactured in China.

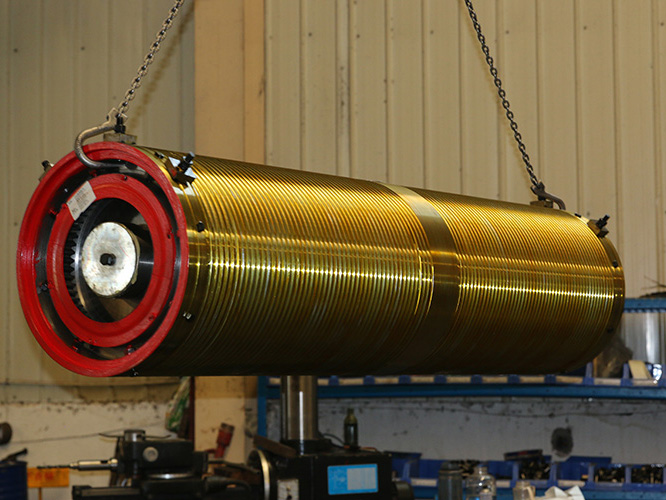

Compared to the commonly used 1,000-ton port cranes, 3,000-ton gantry cranes are distinguished by their large tonnage, heavy lifting capacity, and long spans. They can reach a lifting height of 120 meters, equivalent to the height of a 40-story building. Due to this high lifting height, Weihua Group innovatively designed the largest rope-laying mechanism in China to ensure stable and reliable lifting. Industry experts and professors were also invited to conduct a technical review, and only after successful approval did the crane officially go into production.

It is understood that the main structural components of this 3,000-ton crane are made of rolled steel plates with a maximum width of 3.8 meters. Cutting and welding these plates would be extremely time-consuming and tedious. The sheer volume of production necessitates even higher requirements for thick plate welding and ensuring ultra-high plate flatness. To this end, Weihua Marine decided to reduce the number of welds in the panels and deployed specialized equipment and inspection personnel to ensure quality. This not only improves production efficiency, but also ensures product quality and safety, contributing to overall equipment stability. To meet these production demands, the company also partially upgraded its ultra-large structure plant.

Port and offshore equipment is another high-end equipment manufacturing area that Weihua Group has comprehensively focused on, following its defense and aerospace sectors.