16-Ton Heavy-Duty

Wire Rope Electric Hoist

I. Main Features

High Lifting Capacity: 16 tons falls into the heavy-duty lifting category, suitable for lifting large workpieces, heavy equipment, steel, etc.

Robust Structure: Utilizes a high-strength box-type structure or end beam structure, offering excellent rigidity and the ability to withstand heavy loads and impacts.

Wire Rope Load Capacity: Compared to chain hoists, wire rope hoists offer greater lifting heights (up to tens or even hundreds of meters), smoother operation, and are suitable for medium-to-high speed and frequent use applications.

Drive Method: Typically driven by an electric motor, equipped with a precision gear reduction system, providing powerful and stable lifting force.

High Safety: Standard configuration includes multiple safety devices, such as overload protection, upper and lower limit switches, emergency stop, and phase protection.

II. Main Structural Components of a 16-Ton Heavy-Duty Wire Rope Electric Hoist

A complete 16-ton electric hoist typically includes:

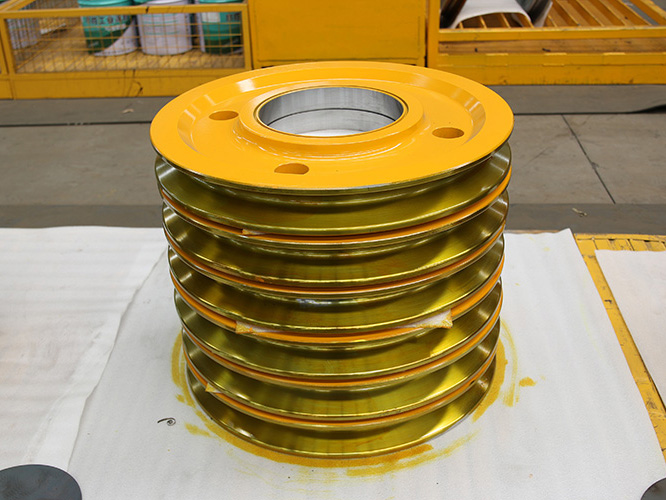

Lifting Mechanism: Motor, gearbox, drum, wire rope, hook.

Operating Mechanism: The motor, wheels, and drive unit that enable the hoist to move horizontally along the track.

Electrical Control System: Control box, remote control (wired or wireless), contactors, limit switches, etc.

Safety Devices: Overload limiter, flameout limit switch, brakes, etc.

III. Typical Application Scenarios of 16-ton Heavy-Duty Wire Rope Electric Hoists

Heavy Machinery Manufacturing and Assembly: Lifting large mechanical components.

Iron and Steel Metallurgy Industry: Lifting steel coils, steel plates, and molten steel ladles (requires a specialized metallurgical hoist).

Ports and Logistics: Loading and unloading heavy cargo in warehouses or storage yards.

Shipbuilding Industry: Handling and installing ship sections, engines, etc.

Power Equipment Installation: Lifting transformers, generators, etc.

Large Equipment Repair Workshops: Used for repairing heavy vehicles, machine tools, etc.

IV. Key Parameters Required for Selecting a 16-ton Heavy-Duty Wire Rope Electric Hoist (Must be specified during inquiry or procurement):

Lifting Capacity: 16 tons.

Lifting Height: How high do you need to lift the goods? (e.g., 6m, 12m, 24m, 30m, etc.). The wire rope length is customized accordingly.

Working Class (Frequency of Use): Commonly M4 (medium) or M5 (heavy-duty). This determines the motor's duty cycle and overall durability.

Operating Speed:

Lifting Speed: Typically single speed (e.g., ~3.5 m/min) or dual speed (normal/slow).

Traveling Speed: The speed at which the hoist moves laterally on the I-beam track (e.g., 20 m/min).

Power Supply: 380V/50Hz/3-phase (domestic standard), other voltage specifications are also available.

Installation Method:

Fixed: Fixed to a bracket or cantilever crane, only lifting and lowering are possible.

Rotating (More Common): Travels on the I-beam track via a matching trolley. The trolley is further divided into manual trolley (human-powered) and electric trolley (motor-driven).

Track type: The specifications of the I-beams used need to be determined based on the wheel pressure of the hoist and trolley (e.g., I40a, I63c, etc.).

Control method: Ground-mounted wired handle (most common), remote control, cab control.

Environmental requirements: Ordinary workshops, high temperature, humidity, explosion-proof (requires special certification), outdoor (requires protective cover), etc.