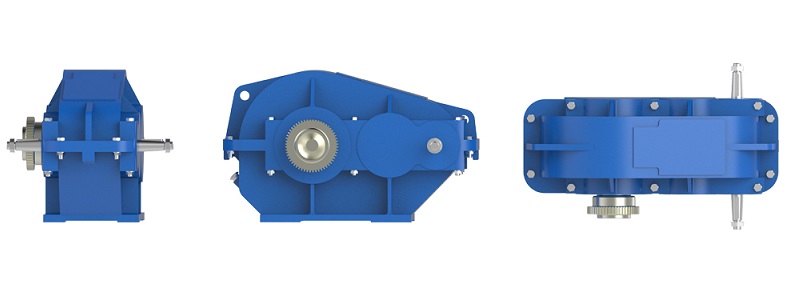

Determining whether a

Weihua crane reducer (crane gearbox) needs replacement hinges on distinguishing between complete machine replacement and component repair. This is primarily based on three dimensions: fault symptoms, degree of damage, and cost-effectiveness of repair. The specific steps and standards for assessment are as follows:

I. Direct Assessment: Prioritize Complete Machine Replacement in the following Situations:

When the crane reducer suffers irreversible structural damage, or the repair cost is close to/exceeds 50% of the cost of a new machine, it is recommended to replace the entire machine directly:

Severe Housing Damage

The cast iron housing of the crane reducer shows cracks or breakage, or the bearing housing is deformed; cracks cannot be repaired by welding (welding easily leads to secondary deformation and seal failure).

Severe rust and deformation of the base mounting surface; even after leveling, coaxiality cannot be guaranteed, affecting transmission stability.

Core Transmission Components Scrap-Level Damage

Gears: Large areas of scuffing, pitting, and peeling on the tooth surface; tooth thickness wear exceeding 15% of the design value; or broken teeth or root cracks (repairing a single broken tooth easily leads to overload damage to other teeth). Shaft System: Input/output shafts are bent, keyways are deformed, and journal wear exceeds limits, making repair impossible through electroplating, welding, or other processes; the bearing inner ring is loosely fitted to the journal (inner ring slippage).

Frequent and Incurable Faults: Recurring oil leaks: Leaks persist even after replacing oil seals and repairing mating surfaces, involving multiple aging and failed sealing points.

Severely Degraded Performance: Severe vibration and abnormal noise under no-load/load conditions, temperature rise exceeding 80℃ (at an ambient temperature of 25℃), and frequent bearing burnout; transmission efficiency drops by more than 20%, failing to meet the rated load requirements of Weihua cranes.

Outdated Model or Poor Compatibility: The

crane reducer (crane gearbox) model is outdated; or the original reducer's speed ratio and torque are incompatible with the crane's operating conditions, requiring upgrades and modifications.

II. Repairability Assessment: Only Parts Need to be Replaced, No Entire Machine Replacement

If the crane reducer housing and shaft system are intact, with only localized component damage, the corresponding parts can be disassembled and replaced: Seal Failure: Only oil seal aging and gasket damage cause oil leakage, with no housing deformation. Bearing damage: Bearing raceway wear, ball spalling, and cage breakage, but the journal and bearing housing fit normally, with no running race.

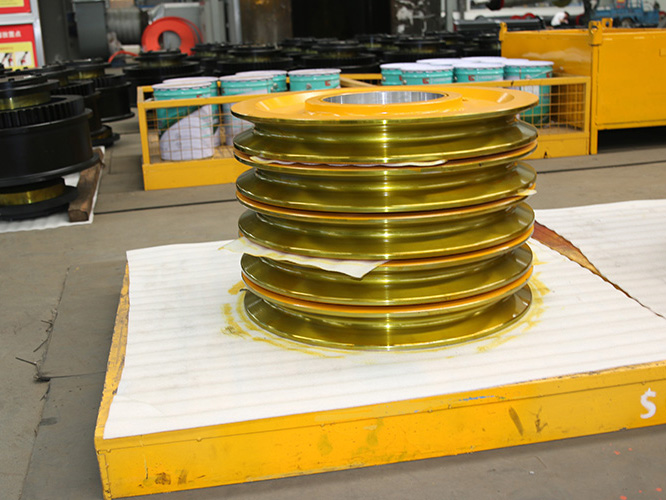

Coupling/Elastomer wear: Coupling tooth surface wear and elastomer cracking; replacement restores transmission accuracy.

Local gear damage: Slight chipping on a single tooth, without affecting other gears; no deformation of the housing or shaft; the entire gear pair can be replaced.

III. Auxiliary judgment indicators: Quantitative evaluation through test data

Vibration and noise detection: Vibration velocity of the crane reducer housing was measured using a vibration meter. At rated speed, it exceeded 4.5 mm/s (National Standard GB/T 6075.3), and spectrum analysis showed abnormal gear meshing frequency, indicating severe wear of transmission components.

Periodic "clicking" noise accompanied by vibration occurred during operation; inspection after shutdown revealed tooth surface damage.

Temperature Rise Detection: After one hour of continuous operation, if the bearing housing temperature exceeds 90℃, or the temperature difference with the ambient temperature exceeds 65℃, and factors such as poor lubrication and poor ambient heat dissipation have been ruled out, it indicates abnormal bearing or gear meshing.

Repair Cost Comparison: If the cost of component repair (including parts, labor, and downtime) exceeds 50% of the new machine price, replacement of the entire machine should be prioritized; if it is less than 50%, repair can be considered.

IV. Special Judgments Based on Crane Operating Conditions: If the

crane reducer is a core component of the hoisting mechanism and directly affects lifting safety, and there are hidden dangers such as broken gear teeth or bent shafts, direct replacement is recommended, and repair is not advised. If it is a reducer for the trolley/gantry traveling mechanism, and the damage is minor and repair can meet the operating requirements, repair can be prioritized.