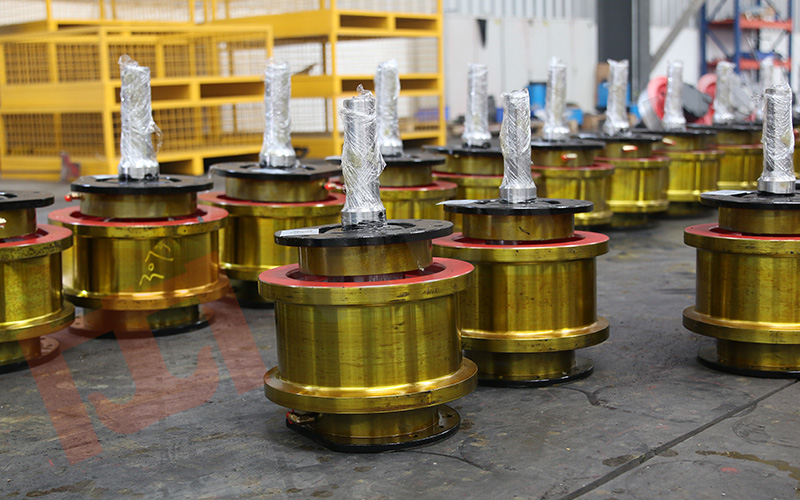

Weihua crane wheels typically have the following characteristics:

Excellent Compatibility: Designed specifically for all Weihua crane series (such as LH type electric hoist bridge cranes, QD type bridge cranes, gantry cranes, etc.), perfectly matching the entire machine system in terms of dimensions, tolerances, and performance.

Reliable Quality: Made of standard steel (such as 65Mn), undergoing standardized

forging/casting crane wheel and heat treatment processes (such as surface quenching) to ensure that hardness, toughness, and wear resistance meet national and industry requirements.

Standardized Production: Wheel specifications are serialized, covering various needs from light and small to extra-large tonnage.

How to Obtain and Select Crane Wheels

Key Identification Information (Please prepare before contacting us)

Equipment Nameplate Information: Record the crane model (e.g., QD50/10t-22.5m A5), product number, and manufacturing date.

Used Crane Wheel Specifications (if replacing):

Wheel Diameter (e.g., φ400mm, φ500mm)

Flange Width and Height

Axle Hole Dimensions (Diameter and Keyway Dimensions)

Total Thickness/Wheel Width

Rail Type (Wheel must match the rail, e.g., QU80, P50, etc.)

Photos: Clear photos of the wheel as a whole, side view, tread, and axle hole details.

Replacement and Maintenance Crane Wheel Special Notes

Original vs. Third-Party: For safety and performance, it is strongly recommended to use wheels from Weihua original parts or their rigorously certified suppliers. Third-party parts, if not sized or heat-treated correctly, can lead to serious problems such as rail wear, premature wear, and even breakage.

Replace in Pairs: Wheels on the same axle (especially the drive side) should be replaced in pairs to ensure consistent diameter and prevent misalignment.

Professional Installation: Replacement must be performed by a professional to ensure: Installation accuracy (levelness, perpendicularity, alignment). Integrity and lubrication of bearings and seals. Correct torque of tightening bolts.

Troubleshooting: If abnormal wear is observed on the wheels (such as severe rail wear), while replacing the wheels, the root cause must be investigated and corrected, such as: track installation accuracy (elevation, straightness, gauge); deformation of the crane bridge or end beams; and asynchronous drive motors.