The reducer (or gearbox) in a crane is a critical component of the transmission system, serving several key purposes:

1. Speed Reduction & Torque Increase

Electric motors typically run at high speed but low torque, while crane operations require low speed with high torque to lift heavy loads. The

crane reducer uses gear mechanisms to reduce the motor's rotational speed while proportionally increasing output torque.

Example: A motor running at 1440 RPM may be reduced to 20 RPM, multiplying torque by a factor of 50 or more.

2. Precise Motion Control

The crane reducer ensures smooth acceleration and deceleration, preventing sudden jerks that could cause load swinging.

It enables accurate positioning, especially in applications like hoisting, trolley travel, and slewing motions.

3. Protection of Motor & Drivetrain

Absorbs shock loads—reducers handle sudden force impacts during lifting, reducing stress on the motor and mechanical parts.

Some reducers include safety clutches or overload protection to prevent damage in case of excessive load.

4. Matching Different Operational Needs

Different crane mechanisms require specific speed-torque ratios:

Hoisting mechanism: High torque, low speed (e.g., 1:50 ratio).

Travel mechanism: Moderate speed for smooth movement.

Slewing mechanism: Controlled rotation for precise positioning.

5. Improving Efficiency & Durability

High-efficiency gear designs (e.g., helical or planetary gears) minimize energy loss.

Enclosed housings protect gears from dust and ensure proper lubrication, extending service life.

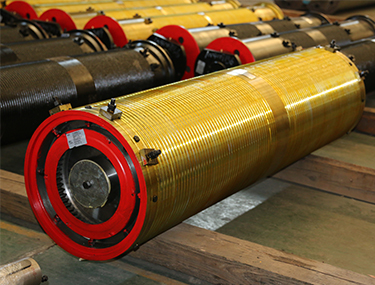

Common Types of Reducers in Cranes

Gear Reducers: Robust and efficient (common in hoisting systems).

Worm Gear Reducers: Self-locking feature (prevents load drop if power fails).

Planetary Reducers: Compact, high torque-to-size ratio (used in space-constrained applications).

Conclusion

The reducer acts as a "power converter" in cranes, transforming motor speed into usable force for lifting and moving loads safely and efficiently. Its performance directly impacts lifting capacity, stability, and operational lifespan.