Weihua can provide all kinds of crane hook blocks, including light hooks (0.5t-20t), heavy hooks (20t-500t), forged hooks, laminating hooks, and specialized hook sets for special conditions. All crane hook models can be customized, including load capacity and color. We support factory SGS inspection before shipment. Our technical team can provide you with the best lifting solutions. For product selection or technical consultation, please feel free to contact us.

High strength and durability

·Forged with high-quality alloy steel (such as 20CrMo, 34CrMo, etc.), after heat treatment (quenching + tempering), the tensile strength can reach more than 700MPa, wear and impact resistance, and the service life is increased by 30%-50%.

·Surface galvanizing or spray anti-corrosion treatment, suitable for humid and corrosive environments (such as ports and chemical fields).

Safety redundancy design

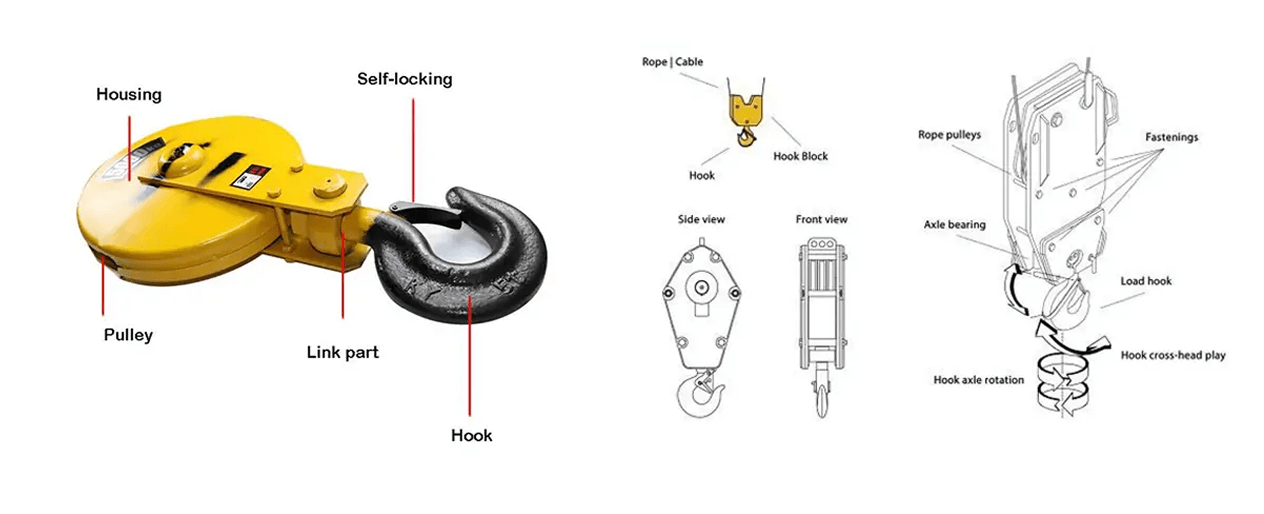

·Standard anti-unhooking devices (such as spring locks, flap locks), in line with international safety standards such as ISO8305 and DIN15400, prevent accidental slippage of rigging during lifting.

·Safety factor ≥ 4:1 (breaking strength more than 4 times the rated load), certified by third-party organizations (such as TUV, CE).

Modular and multi-functional adaptation

·Quick-change hook design (such as CROSBY's Shur-Loc system), different types of slings (such as container hooks, rotating hooks) can be replaced within 3 seconds.

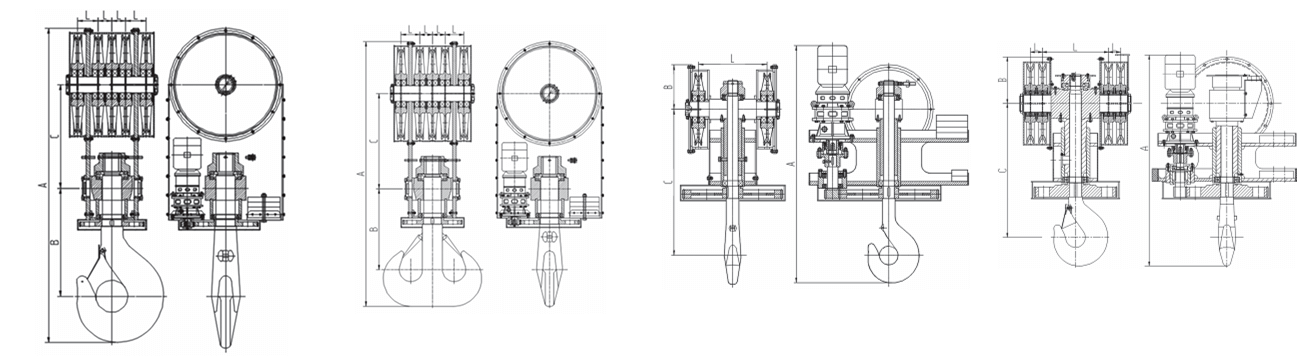

·The tonnage covers 0.5-1000 tons, supports single hook, double hook, combined hook and other configurations, and is suitable for various equipment such as bridge cranes, tower cranes, and truck cranes.

Ergonomic optimization

·Low deadweight design (15%-20% lighter than traditional hooks) reduces equipment energy consumption; streamlined structure reduces air resistance during lifting.

·360° rotating bearing option to achieve torque-free lifting, especially suitable for long materials such as wind turbine blades and pipes.