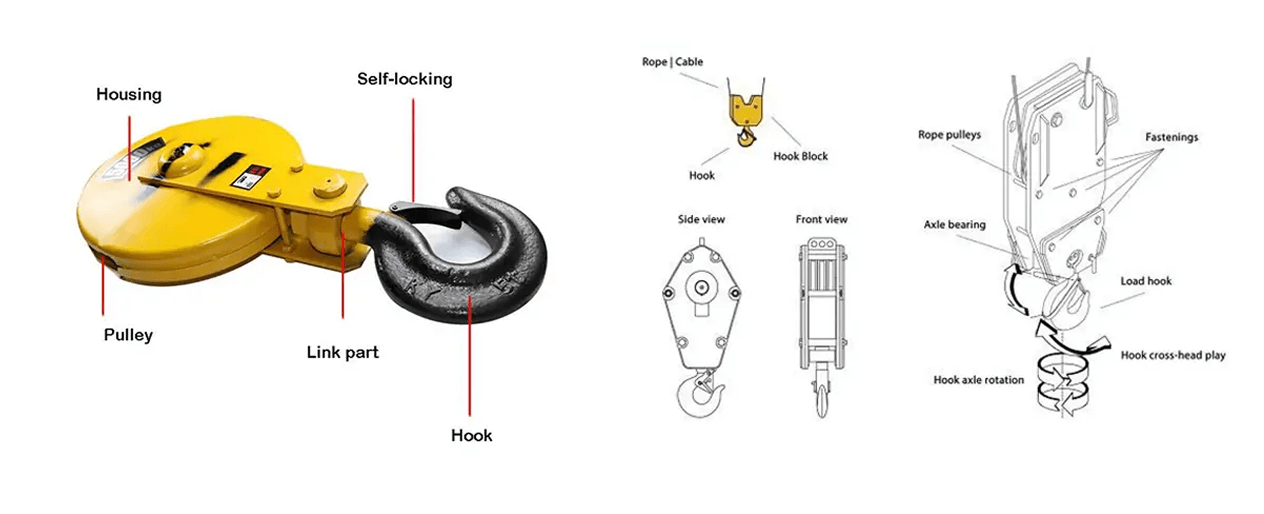

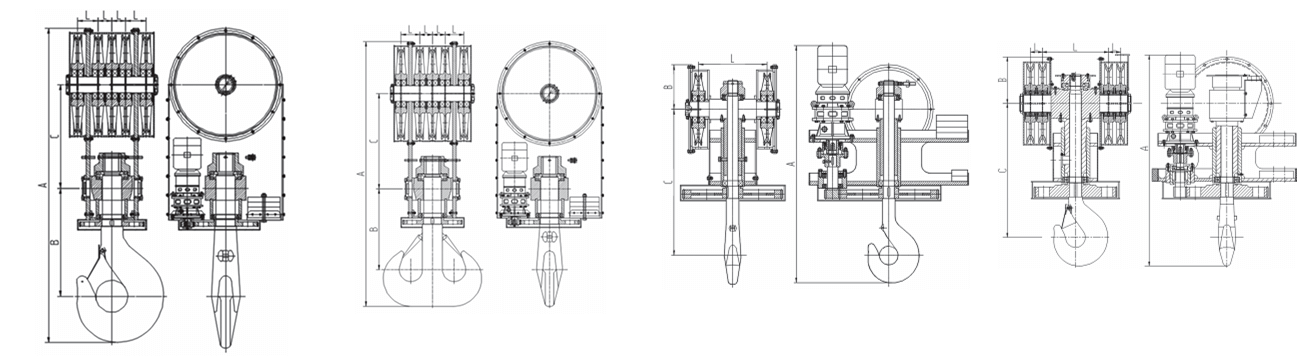

The hook of a bridge crane is one of the core components of a lifting machine. It is usually made of high-quality alloy steel forging or riveted with steel plates, and has the characteristics of high strength, wear resistance and impact resistance. The hook is mainly composed of a hook body, a hook neck, a hook handle and other parts, and is connected to the lifting mechanism through a pulley block to achieve the lifting and handling of heavy objects. According to the manufacturing process, the hook can be divided into a forged hook (strong integrity, suitable for large tonnage) and a laminated hook (riveted by multiple layers of steel plates, which can be partially replaced when damaged).

The safety design of the bridge crane hook includes anti-unhooking devices (such as spring locks), overload protection, and regular inspections (such as opening deformation inspection and crack detection). Its rated load must strictly match the working level of the crane, and overloading is prohibited. Daily maintenance requires checking wear, deformation and lubrication to ensure compliance with relevant industry standards.

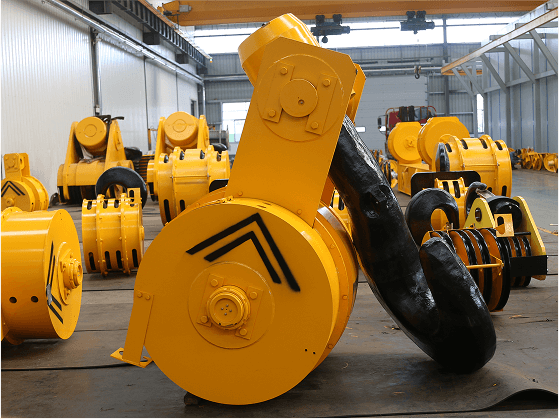

The flexibility and durability of the bridge crane hook make it widely used in factories, warehouses, ports and other scenes, and it is an indispensable key component in material lifting operations.

The bridge crane hooks produced and supplied by Weihua Crane have the advantages of high strength, good durability, safety and reliability, good adaptability, and easy maintenance. They can also be customized according to customer needs. We sincerely welcome customers to contact us quickly.