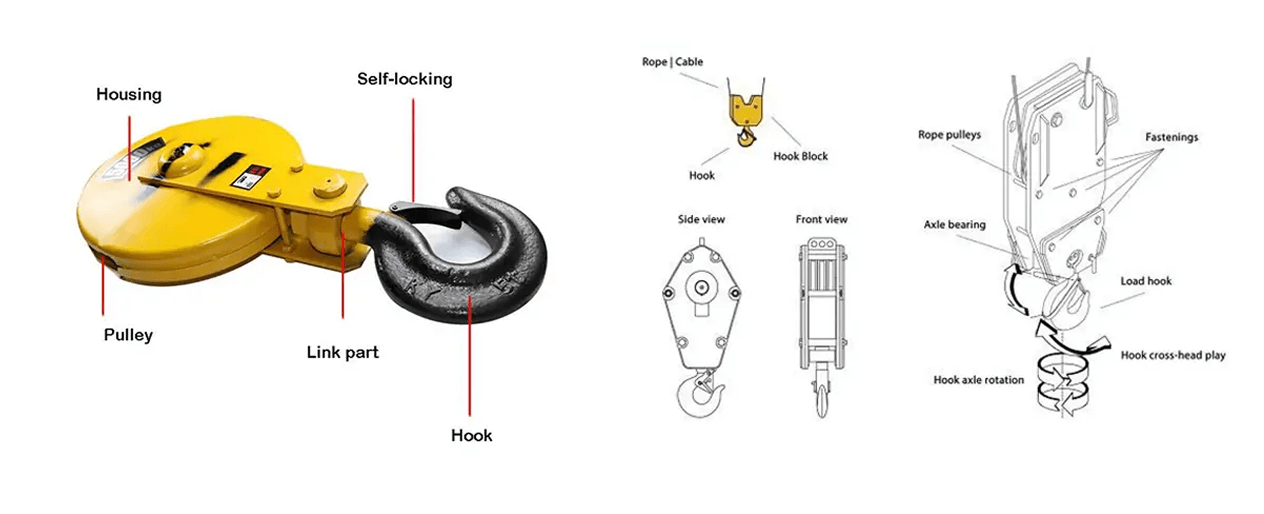

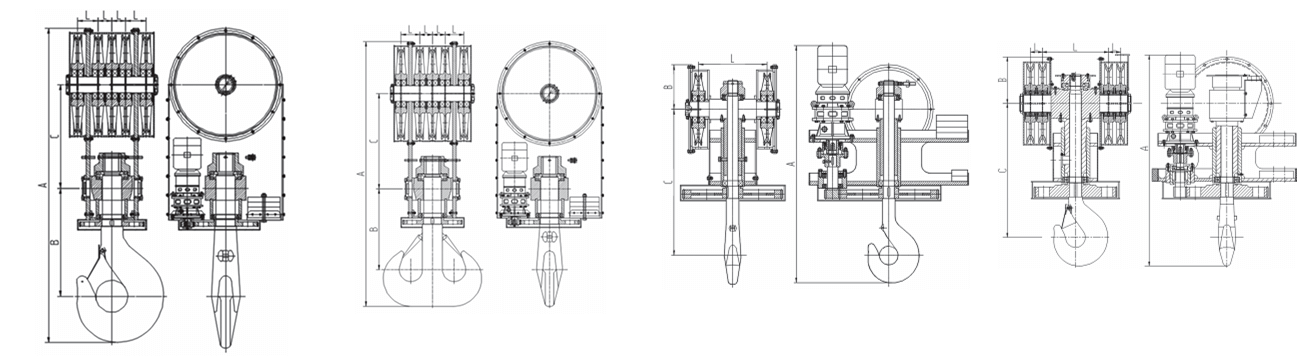

The hook of a bridge crane is one of the core components of lifting equipment, mainly used for hanging and carrying heavy objects. It is usually forged from high-strength alloy steel and has high tensile strength and wear resistance. The structure of the hook includes three parts: the hook body, the hook neck and the hook handle. Some hooks are also equipped with a safety lock device to prevent the heavy objects from accidentally falling off. According to the use requirements, the hook can be divided into two types: single hook and double hook, which are suitable for lifting operations of different tonnages.

To ensure the safety of the operation, the hook must comply with national or industry standards (such as GB/T 10051 "Lifting Hook"). Before use, check whether the surface of the hook has cracks, deformation or severe wear, and perform flaw detection regularly. Daily maintenance includes lubricating the rotating part of the hook neck, cleaning rust and debris, and avoiding overloading. If the hook opening is found to exceed 15% of the original size or the torsional deformation exceeds 10°, it must be replaced immediately.

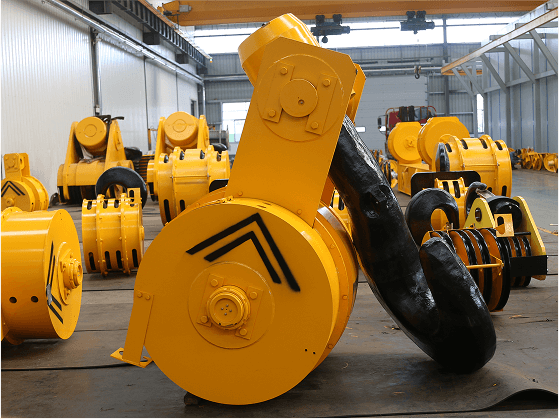

Bridge crane hooks are widely used in material handling in factories, ports, warehouses and other places. When selecting a model, you need to consider the rated lifting capacity, working level (such as M4-M6) and use environment (such as explosion-proof and anti-corrosion requirements). For frequent operations or heavy lifting, it is recommended to use double hooks or add pulleys to disperse the force. In addition, special working conditions (such as high temperature and low temperature) require the use of hooks of corresponding materials to ensure safety and durability.